A Brief Guide To Plasma Cutter

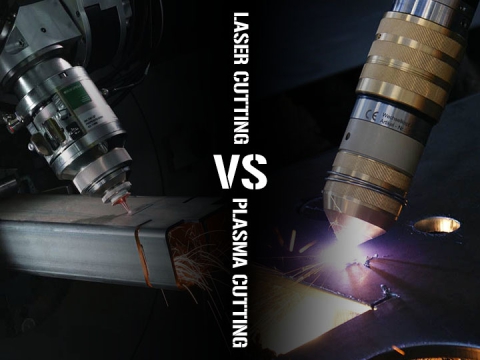

Plasma cutter is a power tool that uses plasma cutting technology to process metal materials. With different working gases, it can cut all kinds of metals that are difficult to cut by oxygen, especially for non-ferrous metals (stainless steel, aluminum, copper, titanium, nickel). The opposite of the plasma cutting machine is the flame cutting machine, and the 2 cutting methods are different.

Plasma cutting is a processing method that uses the heat of a high-temperature plasma arc to partially or partially melt (and evaporate) the metal at the incision of the workpiece, and uses the momentum of the high-speed plasma to remove the molten metal to form an incision. Plasma cutting with different working gases can cut all kinds of metals that are difficult to cut with oxygen, especially for non-ferrous metals (stainless steel, aluminum, copper, titanium, nickel). The cutting effect is better; its main advantage is that the thickness of the metal is not large. At this time, plasma cutting speed is fast, especially when cutting ordinary carbon steel sheet, the speed can reach 5-6 times that of oxygen cutting method, the cutting surface is smooth, the thermal deformation is small, and the heat affected zone is less.

Plasma cutters are widely used in automobiles, locomotives, pressure vessels, chemical machinery, nuclear industry, general machinery, construction machinery, steel structures, ships and other industries.

Plasma cutter with different working gas can cut all kinds of metals that are difficult to cut by oxygen, especially for non-ferrous metals (stainless steel, aluminum, copper, titanium, nickel), the cutting effect is better; its main advantage is to cut metals with small thickness When cutting, the plasma cutting speed is fast, especially when cutting ordinary carbon steel sheets, the speed can reach 5-6 times that of the oxygen cutting method, the cutting surface is smooth, the thermal deformation is small, and there is almost no heat-affected zone.

The plasma cutting machine has developed to the present, the available working gas (the working gas is the conductive medium of the plasma arc, it is also the heat carrier, and at the same time the molten metal in the incision must be removed). The cutting characteristics, cutting quality and speed of the plasma arc are all There are obvious effects. Commonly used plasma arc working gases are argon, hydrogen, nitrogen, oxygen, air, water vapor and some mixed gases.

In recent years, new technologies of fine plasma or high-precision plasma have been widely used, with very good results. By improving the design of the cutting moment, the quality of the cutting surface of the workpiece is significantly improved. The verticality of the shaft edge can reach 0-1.5°, which is especially beneficial to improve the cutting quality of thick plates. Due to the improved cutting gun, the electrode life has been increased several times. However, the distance between the cutting torch and the steel plate is relatively high, and the h8 sensor on the cutting torch is required to be more sensitive and the cutting torch to react faster. Therefore, plasma cutting of 4-30 mm steel plates is an ideal method, which can avoid the shortcomings of low oxygen and oxygen deficiency, large deformation, serious cutting and serious slagging.

In some small and medium-sized enterprises and even in some large enterprises, manual cutting and semi-automatic cutting are more common. The cutting volume of steel in the machinery industry is very large. With the development of the modern machinery industry, the requirements for the work efficiency and product quality of sheet metal cutting are also increasing. Therefore, the market potential of CNC plasma cutting machines is still very large, and the market prospects are relatively optimistic.