How Much Is A Plasma Cutting Table?

These days, a wide range of industries depend on plasma-cutting technology. It cuts through many types of metal quickly and precisely. Using a high-velocity plasma stream of ionized gas, the most recent technique melts the metal to produce clean, accurate cuts. Plasma cutting tables automate this cutting process, allowing operators to provide precise results with less human work. These tools are widely used in manufacturing, construction, and the car industry, among other sectors where efficiency and accuracy are vital.

It is important for anyone considering buying one of these equipment to be aware of the costs associated with plasma cutting tables. Size, power, and technology are some key elements that influence cost. This post will discuss the standard price ranges for several types of plasma cutting tables, the factors influencing these costs, and the variety of options available. After reviewing this article, readers will have a better understanding of what to anticipate when planning a budget for a plasma cutting table.

What is the Cost of Owning a Plasma Cutting Table?

While choosing a plasma cutting table, price is a crucial consideration. A few factors that could result in a wide range of prices are size, power, and features. To help you make an informed purchase, we'll examine the various price ranges and the variables that affect them in this section.

Entry-Level Plasma Cutting Tables

Entry-level plasma cutting tables typically cost between $2,000 and $5,000. These tables are appropriate for minor projects and light-duty activities. They frequently have manual controls and simple functionality.

Mid-Range Plasma Cutting Tables

The usual price range for mid-range plasma cutting tables is $5,000 to $15,000. These devices have more features and perform better. For companies who need to cut heavier metal and a greater range of materials, they are perfect. For more accuracy, mid-range models frequently have CNC capability.

High-End Plasma Cutting Tables

The price range for high-end plasma cutting tables is from $15,000 to over $100,000. These devices are built for heavy workloads and industrial applications. They have more sophisticated features like bigger work surfaces, faster cutting rates, and automated controls. The improved quality and technology utilized in its construction are reflected in the higher cost.

Additional Features That Affect Cost

High-definition cutting, integrated software, and sophisticated cooling systems are examples of extra features that can affect cost. Although these characteristics can improve effectiveness and performance, they may raise the table's total cost. When choosing the best plasma cutting table for their unique requirements, customers can make more educated judgments if they are aware of these price points and characteristics. It guarantees they receive the highest return on their investment.

Types of Plasma Cutting Tables Available in the Market

When choosing a plasma cutting table, understanding the different types available is essential. Each type is designed for specific applications and needs. Knowing these differences helps you select the right table for your projects and ensures optimal performance.

Manual Plasma Cutting Tables

The cutting torch on these tables must be manually controlled by the operator. Although they are typically less expensive, using them successfully takes more experience and ability. Smaller jobs and basic cuts are appropriate for manual tables. However, depending on the operator's expertise, the precision may vary and the learning curve may be steep.

CNC Plasma Cutting Tables

The cutting operation is automated by Computer Numerical Control (CNC) tables. They can create intricate designs and precise cuts because they use a computer to regulate the torch's movement. Due to their superior technology, CNC tables are usually more expensive. Their large volume production capabilities and ability to maintain consistency across many sections make them a popular choice in industrial environments.

Portable Plasma Cutting Tables

These are smaller and designed for easy transportation. They are ideal for fieldwork and smaller projects. While they are often less expensive, they may not offer the same cutting power as larger models. Portable tables are excellent for contractors who need flexibility on job sites and can handle various metal thicknesses within their limits.

High-Definition Plasma Cutting Tables

The greatest level of precision is offered by these advanced tables. They have characteristics that enable complex cuts on a variety of materials. But they are more expensive; they frequently cost more than $30,000. For businesses like aerospace and automobile manufacturing, where even small errors can have serious consequences, high-definition plasma tables are ideal.

Popular Plasma Cutting Table in the Market

Small Entry-Level 4x4 CNC Plasma Table

The STP1212 from STYLECNC is an entry-level CNC plasma table with a 4x4 working area, which is designed for hobbyists seeking precision cutting capabilities in metal fabrication. The 4x4 plasma cutting table comes with a rugged construction to ensure durability and stability during operation, while the user-friendly software makes it easy for beginners to use. Overall, this small plasma cutting table is considered a great and affordable investment for DIYers and artists, whether they are looking to improve their metalworking capabilities or increase their creativity and productivity in metal fabrication.

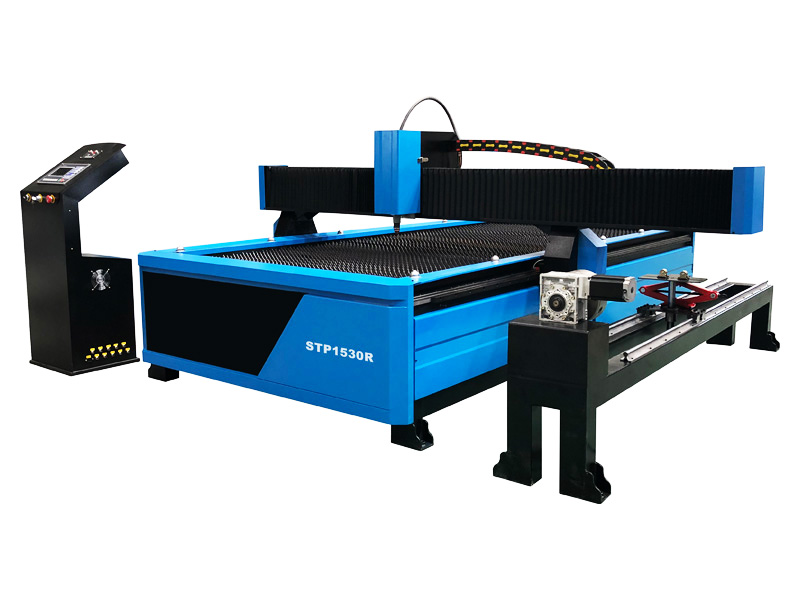

Top Rated Professional 4x8 CNC Plasma Cutting Table

The best 4x8 CNC plasma cutting table of 2024 from STYLECNC is designed for professionals working on precise sheet metal cutting with a 48" x 96" bed size. It supports various power options, including Hypertherm and Huayuan, with cutting capacities up to 40mm. The machine features a Starfire control system, automatic torch h8 control (THC), and FastCAM software for material-saving nesting.

Its sawtooth or blade table design ensures stability, while optional rotary devices allow for metal tube cutting. The table offers high precision, versatility, and efficiency, making it ideal for industries such as fabrication, automotive, marine, and signage. Regular maintenance and proper calibration ensure long-term performance and productivity.

Industrial 5x10 Hypertherm Plasma Cutter Table

The 5x10 Hypertherm plasma cutter table from STYLECNC is a high-performance machine designed for precise and efficient metal cutting in industrial manufacturing. It features a 1500x3000mm cutting table and supports rotary cutting of pipes with diameters from 200mm to 600mm. Powered by options like Hypertherm Powermax (45A to 200A) or Huayuan, it can handle materials up to 40mm thick. The machine integrates a Starfire CNC control system, HYD torch h8 controller, and dual-motor Y-axis drive with Taiwan Hiwin linear rails for smooth and precise operation.

The advanced features of STYLECNC's plasma cutting table include lubrication systems, auto-fume extraction, and flexible configurations for both sheets and tubes. Its high speed, robustness, and reliable performance make it perfect for use in industries such as aerospace, manufacturing, and shipbuilding. To improve operator safety, safety features like emergency stops, voltage monitoring, and thermal overload protection are included. It provides thick metal manufacturing at a lower cost with optimal energy consumption when compared to fiber laser cutters.

Factors That Influence the Cost of Plasma Cutting Tables

Several factors can affect the cost of a plasma cutting table. Understanding these can help buyers find the right machine for their needs.

• Size of the Table: Larger tables can accommodate bigger sheets of metal. They generally cost more due to their size and increased capabilities.

• Power Requirements: Plasma cutters come in various power ratings, which affect cutting speed and thickness. Higher power machines are more expensive but offer greater cutting capabilities.

• Brand Reputation: Established brands often charge more for their machines. However, they typically provide better quality and reliability, making them a worthwhile investment.

• Additional Features: Features like CNC automation, advanced software, and improved cooling systems can increase the price. Buyers should assess which features are essential for their work.

Additional Costs to Consider

In addition to the initial purchase price, there are other costs to consider when buying a plasma cutting table. Understanding these expenses can help you plan your budget effectively.

Software

Many machines require specialized software for operation. This can range from $500 to $5,000, depending on the capabilities. The right software can significantly enhance the cutting process, enabling more complex designs and better precision. Investing in high-quality software ensures you get the most out of your plasma cutter.

Maintenance

Sufficient performance requires routine maintenance. This involves changing out wearable components like electrodes and nozzles, which raises continuous expenses. Maintaining your machine not only makes it last longer but also makes sure it runs well. Ignoring maintenance can cost you money in repairs and cause downtime, which lowers production.

Consumables

Plasma cutting requires consumable materials that need regular replacement. Budgeting for these can help avoid unexpected expenses. Consumables can include electrodes, nozzles, and plasma gas, all of which are necessary for effective cutting. Keeping a close eye on your inventory of consumables ensures you won’t face interruptions during critical projects.

Accessories

The price of the item may also increase with additional accessories like toolboxes, clamps, and safety equipment. You should account for these in your budget. To shield personnel from potential risks during the cutting process, safety equipment is essential. Good clamps and toolboxes can improve productivity and coordination, which will improve workspace efficiency overall.

Is Buying a Used Plasma Cutting Table a Good Option?

Buying a used plasma cutting table can be an appealing option for many businesses. It offers a chance to save money while still acquiring a valuable piece of equipment. However, it is important to weigh the advantages and disadvantages before making a decision.

Pros of Buying a Used Plasma Cutting Table

• Cost Savings: Used machines are typically cheaper than new ones, allowing buyers to access higher-quality models without breaking the bank.

• Less Depreciation: Purchasing a used machine often means experiencing less depreciation, helping you maintain more of your investment over time.

• Opportunity for Upgrades: With the savings, you may afford a more advanced model or additional accessories, enhancing your overall capabilities.

Cons of Buying a Used Plasma Cutting Table

• Wear and Tear: Used machines may show signs of wear, which can impact performance and cutting precision, leading to unexpected maintenance costs.

• Outdated Technology: Older models may lack the latest features and capabilities, hindering productivity in a fast-paced industry.

• Limited Warranty: Used machines often come with limited or no warranties, increasing the risk if something goes wrong shortly after purchase.

Before buying a used plasma cutting table, it is crucial to conduct a thorough inspection. Understanding the machine's history, previous usage, and maintenance records can help you make an informed decision. By weighing these pros and cons, you can determine if a used plasma cutting table is the right option for your needs.

Final Words

It's important to carefully examine your goals and budget while selecting the best plasma-cutting table. Determine the kinds of materials you plan to cut and the amount of work you anticipate before beginning. Entry-level variants of plasma cutting tables typically cost $2,000, while high-end industrial units can cost over $100,000. It's critical to assess your budget and account for any supplemental expenses for consumables, maintenance, and software.

Investing in a well-chosen plasma cutting table can significantly boost productivity and efficiency. By taking into account the costs and features, together with any potential savings from buying used equipment, you can make an informed choice. Knowing what types are available and what their price ranges are will help you choose a table that meets your needs without going over your budget. Your cutting operations will operate profitably and efficiently over the long term if you make wise investments.