Is There a Reliable Portable CNC Machine?

Portable CNC machines have become a must-have tool for hobbyists, small business owners, and professionals who need precision and mobility in one compact package. These machines are designed to be easy to transport while still delivering the same level of accuracy and quality as their larger counterparts. Whether you're working on-site, in a small workshop, or need flexibility for various projects, portable CNC machines make it possible to tackle a wide range of tasks without taking up too much space.

In this article, we'll dive into the key features that make a CNC machine truly portable and why these machines are perfect for small-scale projects. We’ll also explore how they compare to larger models in terms of precision, and their impact on the manufacturing industry, and provide tips on choosing the right machine for your needs. Ready to explore the world of portable CNC? Let’s get started!

What Makes a CNC Machine Truly Portable? Key Features to Look For

When you're in the market for a portable CNC machine, it's important to know what specific features make a machine truly portable without sacrificing precision or functionality. A portable CNC machine should not only fit into your workspace but also be easy to move from one job site to another. For professionals working in various locations, having a lightw8 and versatile machine that doesn't compromise on quality can make all the difference. This guide covers the essential features that ensure portability while maintaining the high standards needed for CNC operations.

Knowing about the key features that define a portable CNC machine will help you make an informed decision, whether you're setting up a mobile workshop or need flexibility for on-site work. Below, we break down these features and why they matter when choosing the right machine for your needs.

Key Features to Look for in a Portable CNC Machine

• Compact Design and Lightw8 Build: Portability starts with the design. A CNC machine that’s easy to move around should have a compact structure that doesn't take up much space. Choose a machine made with lightw8 materials that offer durability without the weight, making transportation easier.

• Power Source Flexibility: Being able to use the machine in various locations requires flexibility in power options. Look for machines that can run on standard electrical outlets or even have the ability to work with alternative power sources like batteries, making them adaptable to remote work environments.

• User-Friendly Interface: A portable CNC machine should have an intuitive interface that makes operation simple, even for beginners. Easy-to-navigate software and controls are essential for making quick adjustments and ensuring smooth operation when you’re on the go.

• Durability and Robustness: Even a portable machine needs to be tough. Check for solid construction, such as a sturdy frame, that can withstand the rigors of frequent movement. A durable CNC machine ensures that even in transit, it will maintain accuracy and longevity.

• Quick Setup and Tear Down: Look for machines that can be set up or packed away quickly. The more efficient the setup process, the less time you spend on prep and teardown, especially when moving between jobs or locations.

• High Precision in a Small Package: A portable CNC machine should not sacrifice precision for portability. It’s crucial that even in a smaller form, the machine delivers the same level of accuracy as its larger counterparts to ensure your projects meet professional standards.

Top Benefits of Using a Portable CNC Machine for Small-Scale Projects

Portable CNC machines are designed to be compact, lightweight, and highly efficient, making them the perfect choice for those who need precision and mobility without sacrificing quality. Whether you’re a hobbyist or a small business owner, portable CNC machines can improve your workflow and save you time and resources. Let’s explore the top benefits that come with using these machines for your small-scale projects.

Increased Flexibility and Mobility

Portable CNC machines allow you to work in different environments, whether it’s a workshop, an on-site project, or at a client’s location. This flexibility helps you take on a wider range of jobs without the need for a large, permanent setup, making it easier to meet the demands of your customers.

Cost-Effective Solution

For small-scale projects, investing in a portable CNC machine can be more affordable than traditional larger machines. They offer the same high-level precision and efficiency but at a fraction of the cost, making them an ideal solution for businesses with a limited budget or hobbyists just starting.

Space-Saving Design

Portable CNC machines are compact and can be stored easily when not in use. If you have limited space in your shop or workspace, a smaller CNC machine allows you to maximize the area available without compromising on your project quality.

Ease of Use and Setup

Most portable CNC machines are user-friendly and require minimal setup time, allowing you to start working right away. This can be especially beneficial for small-scale projects where time is of the essence, helping you complete tasks faster and with fewer hassles.

Precision and Quality in Small-Scale Work

Despite their small size, portable CNC machines maintain the same high level of precision as their larger counterparts. Whether you’re cutting wood, plastic, or metal, these machines ensure that your small-scale projects are executed with accuracy and attention to detail, leading to professional results every time.

Reduced Overhead Costs

Since these machines are portable and versatile, you can use them for a variety of tasks without needing to invest in multiple machines. This helps reduce overhead costs, as you don’t have to purchase specialized equipment for each job.

Are Portable CNC Machines as Accurate as Their Larger Counterparts?

Portable CNC machines have gained popularity for their flexibility and compact design, but one common question that arises is whether they can match the precision of their larger counterparts. While portable CNC machines may not have the sheer size and power of industrial models, they can still deliver exceptional accuracy for most small-scale projects. Thanks to advancements in technology, many portable machines are designed to achieve high precision levels comparable to larger machines.

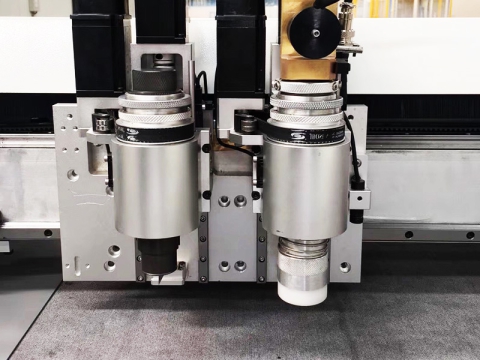

These machines often use advanced control systems, high-quality spindles, and precision components that enable them to perform intricate tasks with minimal error. For many tasks such as engraving, small part cutting, and detailed carving, portable CNC machines can offer results that are just as accurate as larger models, all while being more cost-effective and space-efficient.

Consistent Precision with Smaller Jobs

Portable CNC machines are ideal for smaller-scale operations and can handle intricate designs with impressive accuracy. They are built to cut, carve, and engrave on various materials with a high degree of precision, making them perfect for hobbyists, makers, or small businesses focusing on detail-driven projects.

Ideal for Prototyping and Custom Work

Portable machines are often used in prototyping and one-off custom jobs where precision is crucial. They can produce parts with tight tolerances that meet the needs of industries such as jewelry, custom signage, and electronics.

Precision Technologies Used

Modern portable CNC machines come equipped with features like high-precision stepper motors, ball screw mechanisms, and advanced CNC controllers. These components contribute to achieving better accuracy, even in machines that are smaller and lighter than their industrial counterparts.

The Impact of Portable CNC Machines on the Global Manufacturing Industry

Portable CNC machines have made a significant impact on the global manufacturing industry, offering benefits that were once exclusive to large-scale operations. These compact machines provide manufacturers with flexibility, cost-efficiency, and access to precision in ways that were previously out of reach for smaller businesses or individual makers.

One of the key advantages is the ability to work on-site or in smaller workshops, eliminating the need for expensive industrial setups. This has democratized manufacturing, enabling startups and small businesses to enter the market without hefty upfront costs. Additionally, portable CNC machines allow for faster prototyping, which is essential for industries that require rapid iteration, like product design and innovation.

They’ve also improved accessibility for manufacturers in remote or underserved regions, reducing the dependency on large factories. This accessibility fosters local production, helping to shorten supply chains and reduce lead times. Overall, portable CNC machines have shifted the dynamics of the manufacturing industry, enabling more businesses to compete on a global scale and helping speed up production processes in diverse industries.

How to Choose the Right Portable CNC Machine for Your Needs?

Choosing the right portable CNC machine for your needs can be a game-changer, whether you're a hobbyist, small business owner, or part of a larger operation. The right machine will offer precision, efficiency, and versatility without taking up too much space or breaking the bank. Here’s how you can approach the selection process step by step:

Step 1: Define Your Project Requirements

Before diving into specifications, take a moment to consider the materials you'll be working with, the complexity of your designs, and your desired production speed. Are you primarily cutting wood, metal, or plastic? This will guide you toward the right machine.

Step 2: Consider Size and Portability

Since you’re looking for a portable CNC machine, its size and w8 should be top priorities. Check if it can fit in your workspace while still offering the capacity to handle your projects. A compact yet robust machine can help you work efficiently without sacrificing mobility.

Step 3: Look at the Machine’s Precision and Accuracy

Precision is key in CNC work. Make sure the machine you choose provides the level of accuracy you need for your designs. Check the specifications for repeatability and resolution to ensure it can handle the intricacies of your projects.

Step 4: Evaluate the Control System and Software Compatibility

Look for a machine with an easy-to-use control system that works well with your preferred CAD/CAM software. User-friendly interfaces and software compatibility can significantly reduce the learning curve and improve your workflow.

Step 5: Assess Power and Performance

Portable CNC machines come with varying power ratings. Ensure the machine has the right motor power and speed to meet your production needs. A machine that strikes the right balance between power and efficiency will make your projects run smoothly.

Choose a brand with a strong reputation for customer service and support. A good warranty and after-sales support can save you time and money in case of any issues down the line.

The Limitations of Portable CNC Machines and How to Overcome Them

Portable CNC machines are a fantastic choice for many small-scale and home-based projects due to their compact size and versatility. However, like any technology, they do come with certain limitations that users should be aware of. One of the most common challenges is the limited workspace or smaller cutting areas compared to larger, industrial models. This can restrict the scale of the projects you can tackle, especially when working with larger materials or more complex designs.

Additionally, portable CNC machines may have lower motor power and cutting speeds, making them less suitable for heavy-duty or high-volume production. Precision might also be a concern, as smaller machines may not offer the same level of repeatability and fine detail that larger machines can provide. Finally, the complexity of programming and limited support for advanced CAD/CAM software may make it harder for users to optimize their machines for specific needs.

Despite these limitations, there are effective ways to overcome these challenges and ensure your portable CNC machine remains productive and efficient. Here are some solutions:

• Maximize Workspace Efficiency: Utilize rotating or adjustable fixtures to handle larger materials in smaller spaces, or consider investing in modular CNC workstations that can be expanded as needed.

• Optimize Cutting Speed and Power: Choose a machine with variable speed and power settings to adjust based on material type, and keep the cutting speeds within recommended ranges to avoid overload.

• Upgrade Precision: For more detailed work, consider investing in high-quality tools and accessories designed to enhance precision, such as precision collets, higher-grade motors, and rigid machine setups.

• Enhance Software Compatibility: Use compatible CAD/CAM software that integrates seamlessly with your portable CNC machine to maximize its capabilities and ensure smooth programming and workflow.

• Regular Maintenance: Perform regular maintenance, such as cleaning the machine, lubricating moving parts, and checking for wear and tear to ensure the machine operates at peak performance.