What is a UV Laser Marking Machine?

UV laser marking machine is developed with a 355nm Ultraviolet laser source for plastic, silicon, glass, and ceramic, which adopts a third-order intracavity frequency doubling technology. Compared with infrared lasers, a 355nm UV laser has a very small focus spot, which can greatly reduce the material mechanical deformation, and the processing heat influence is small. UV laser marking machines are mainly used for ultra-fine marking and engraving. It is especially suitable for food and medical packaging materials, marking, micro-holes, high-speed division of glass materials, and complex pattern cutting of silicon wafers.

Ultraviolet laser marking machines are widely used in some high-end markets for fine processing. For example, some high-molecular materials for cosmetics, marking of flexible PCB boards, micro-controlling of silicon wafers, and 2D code marking of LCD liquid crystal glass, various metals, plastics, building materials, communication equipment (mobile phone screens, mobile phone cases, iPhone cases, Huawei mobile phone cases, Samsung mobile phone cases, OPPO mobile phone cases, XIAOMI mobile phone cases).

How Does UV Laser Marking Machine Work?

The principle of the UV laser marking system is similar to the most common laser marking machines, which use laser beams to make permanent marks on the surface of various materials. The effect of marking is to directly break the molecular chain of the substance through the short-wave laser (different from the evaporation of the surface substance produced by the long-wave laser to expose the deep substance) to reveal the pattern and text to be etched.

Ultraviolet laser marking is a type of cold engraving method. The engraving process is called the "photo etching" effect. "cold processing" has a very high load of energy (ultraviolet) photons, which can break the chemical bond in the material (especially organic material) or the surrounding medium. To cause the material to undergo non-thermal process damage. There is no heating or thermal deformation on the inner layer and nearby areas of the processed surface. The high-energy molecules of ultraviolet photons directly detach the molecules on the metal or non-metal materials that need to be processed. However, this detachment causes the molecules to separate from the material. This way of working does not generate heat, because it does not generate heat. As a result, the method of UV laser processing has become cold processing, which is the source of the difference from traditional fiber laser marking systems.

Why Choose a UV Laser Marking Machine for Plastic, Silicon, Glass, Ceramic

The UV laser marking machine is based on its unique low-power laser beam, so it can perform ultra-fine marking and special material marking. It is the 1st choice for customers who have higher requirements for marking effects. It is especially suitable for the high-end market of ultra-fine processing, with fine effects and clear and firm markings.

The Ultraviolet laser engraving machine has high beam quality and small focused spot, which makes marking finer and higher definition; the heat-affected area is small, no thermal effect is generated, and the deformation or scorching of the processed material is avoided. The applicable materials are particularly wide, which solves the problems of insufficient detail and poor effect of fiber laser engraving for many materials. The marking speed is fast and the efficiency is high. The function of online flying marking can be realized on the assembly line.

Features & Advantages of Desktop UV Laser Marking System for Plastic, Silicon, Glass, Ceramic

1. A UV laser engraving machine adopts 355nm pumped UV laser device, to get smaller diameter of focusing spot and fine marking effect.

2. The metal absorbs UV higher than infrared and is therefore more suitable for UV laser marker marking on metal and glass materials compared with infrared pump machines.

3. A narrower pulse width of UV laser makes a shorter time of processing on materials, thus the materials avoid being deformed or burnt due to thermal.

4. With a smaller heat-affected area and a more beautiful marking effect, our products' UV laser marking system can meet customers with higher marking requirements.

5. The UV laser engraving machine is equipped with a safety shield, which can effectively isolate the purple radiation, to ensure the safety of UV laser marker operators.

6. UV laser engraver is equipped with a professional water cooling machine, air-cooled water circulation cooling, with water-cooled high efficiency and air-cooled small size.

7. Low energy consumption, environmentally friendly, no consumables. Little affected area, no heat effect, without material burned problem.

Technical Parameters of Desktop UV Laser Marking Machine for Plastic, Silicon, Glass, Ceramic

| Model | STJ-3U |

| Laser type | Ultraviolet laser |

| Laser wavelength | 355nm |

| Laser power | 3W |

| Pulse length | <18ns@40kHz |

| Marking area | 110mmX110mm |

| Frequency range | 20kHz-200kHz |

| Min line width | 0.01mm |

| Min character | 0.2mm |

| Accuracy of repetition | ±0.003mm |

| Machine power | <1.8KW |

| Electrical power requirement | 220V/50HZ/60HZ or 110V/60HZ |

Desktop UV Laser Engraving Machine Applications

Applicable Industries:

1. Electronic components, battery chargers, electric wire, computer accessories, mobile phone accessories (mobile phone screen, LCD screen), and communication products.

2. Automobile and motorcycle spare parts, auto glass, instrument appliances, optical devices, aerospace, military industry products, hardware machinery, tools, measuring tools, cutting tools, and sanitary ware.

3. Pharmaceutical, food, beverage, and cosmetics industry.

4. Plastic, glass, crystal, arts and crafts of surface and internal thin film etching, ceramic cutting or engraving, clocks and watches, and glasses.

5. Polymer material, majority of the metal and non-metallic materials for surface processing and coating film processing, previous to light polymer materials, plastic, fire prevention materials, etc.

Applicable Materials:

PP (polypropylene), PC (polycarbonate), PE (polyethylene), ABS, PA, PMMA, Silicon, Glass, and Ceramics.

Types of Plastics You can Engrave with a UV Laser Marking System

Silicone.

Polyamide (PA).

Polyimide (PI).

Polyester (PES).

Polystyrene (PS).

Polyethylene (PE).

Polypropylene (PP).

Polycarbonate (PC).

Polyoxymethylene (POM).

Polyether ketone (PEEK).

Polyarylsulfone (PSU, PPSU).

Polymethylmethacrylate (PMMA).

Polyethylene terephthalate (PET).

Acrylonitrile butadiene styrene copolymer (ABS).

Details of UV Laser Engraver for Plastic, Silicon, Glass, Ceramic

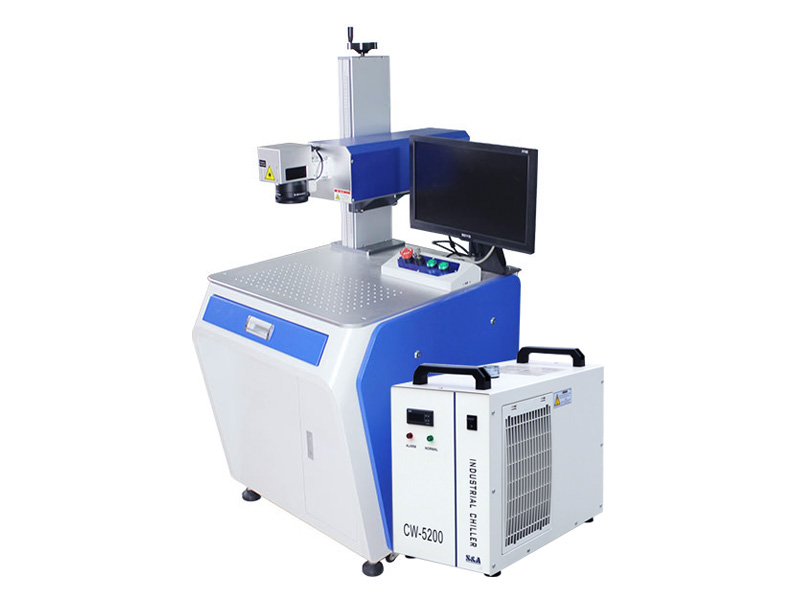

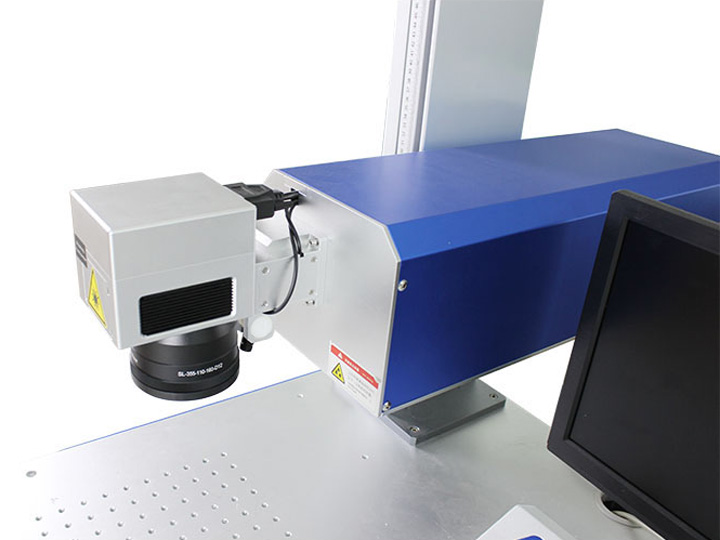

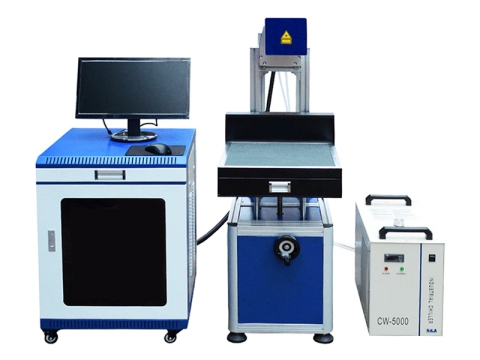

CW-5200 Industrial Water Chiller

3W Ultraviolet laser generator

UV Laser Marking Machine for Plastic, Silicon, Glass, Ceramic Projects

How to Select the Best UV Laser Marking Machine for Your Business?

Selecting the ideal UV laser marking machine is a crucial choice that can affect the productivity, caliber of your products, and overall profitability of your company. Given the abundance of possibilities, it's critical to consider vital criteria before making a purchase. The key factors to take into account when choosing the ideal UV laser marking system for your requirements are broken down below.

1. Understand Your Material and Application Needs

Before purchasing a UV laser marking machine, identify the materials you will be working with, such as plastics, glass, ceramics, or silicon. Different materials react differently to laser marking, so ensuring compatibility is crucial. Also, consider the type of marking—whether it's engraving, etching, or micro-marking—so you choose a machine that meets your specific requirements.

2. Evaluate Laser Power and Wavelength

The 355nm wavelength of UV laser machines is ideal for ultra-fine, high-precision marking, but the power level matters too. Machines with 3W to 10W power are typically suitable for most applications. Higher power means faster processing speeds, but excessive power may not be necessary for delicate or intricate markings. Choose wisely based on your workload and material sensitivity.

3. Consider Marking Speed and Efficiency

If your business requires high-volume production, you need a UV laser marker with fast marking speeds and stable performance. Look for machines that support on-the-fly marking (dynamic marking on production lines) to maximize efficiency. A slow machine can create production bottlenecks, reducing overall output and profitability.

4. Check for Precision and Resolution

A good UV laser marker should offer high resolution (as fine as 0.01mm line width) and repeatable accuracy (±0.003mm) to ensure crisp, clear, and permanent markings. If your business deals with small components, circuit boards, or intricate designs, precision is a top priority. Low-quality machines may leave blurry or inconsistent marks.

5. Assess Cooling and Heat Management System

UV laser marking machines generate heat, but effective cooling systems help maintain stability. Most UV laser markers come with air-cooled or water-cooled options. Water-cooled systems provide superior heat dissipation for extended operation, making them ideal for high-intensity usage. Investing in proper cooling ensures longevity and consistent performance.

6. Prioritize Software Compatibility and Ease of Use

A user-friendly interface and versatile software are essential for smooth operation. Look for machines that support EZCAD or other widely used laser control software for seamless design imports and parameter adjustments. An intuitive system reduces operator training time and minimizes errors, boosting overall productivity.

7. Look for Safety Features and Compliance

Since UV laser technology emits high-energy beams, safety is crucial. Choose a machine with a protective enclosure, laser shielding, and automatic shut-off features to ensure workplace safety. Additionally, check for CE, FDA, or ISO certifications, which indicate compliance with international safety and quality standards.

Desktop vs. Industrial UV Laser Marking Systems

Desktop models are compact and cost-effective, while industrial systems offer higher power and automation for large-scale operations. Choosing between a desktop and an industrial UV laser marking system depends on your production needs, budget, and workspace. Here’s a detailed comparison to help you make the right decision.

| Feature | Desktop UV Laser Marking System | Industrial UV Laser Marking System |

| Size & Portability | Compact and lightweight, easy to move | Large and fixed, designed for high-volume production |

| Power & Performance | Lower power (typically 3W–5W), ideal for small-scale marking | Higher power (5W–15W), suitable for heavy-duty applications |

| Marking Speed | Moderate speed, good for low to medium production | High-speed marking, optimized for continuous production lines |

| Precision & Detail | Excellent precision, suitable for fine engraving | High precision but optimized for bulk processing |

| Cooling System | Air-cooled or small water-cooled systems | Advanced water-cooled systems for extended operation |

| Material Compatibility | Works well with plastics, glass, silicon, and ceramics | Handles a wider range of materials, including metals |

| Workload Capacity | Best for small businesses and workshops | Designed for large-scale factories and production lines |

| Automation Support | Limited automation, mostly manual operation | Can be fully integrated with automated production lines |

| Cost | More affordable, lower initial investment | Expensive but offers better long-term ROI |

| Maintenance | Easier to maintain, and requires minimal upkeep. | Requires regular maintenance due to high workload |

Through the above content, everyone has a certain understanding of the UV laser marking machine for plastic, silicon, glass, ceramic, and crystal. When you start to buy, you need to compare from many aspects, like the quality and service, you can’t just judge from the price. If you have any questions, you can get a free quote from STYLECNC.

Getting the Best UV Laser Marking Machine: Why STYLECNC is a Trusted Choice?

When investing in a UV laser marking machine, quality, precision, and long-term reliability matter. STYLECNC has established itself as a trusted brand in the laser industry, offering cutting-edge solutions for plastic, silicon, glass, and ceramic markings. Here’s why STYLECNC stands out as the best choice for your marking needs.

1. STYLECNC's UV laser marking machines use 355nm ultraviolet laser technology, ensuring ultra-fine marking with minimal heat impact. This prevents material deformation and enhances marking accuracy, making them ideal for high-detail engraving on delicate surfaces like electronics, medical devices, and plastics.

2. Built with high-quality components, STYLECNC machines offer consistent performance and long-lasting durability. The efficient cooling system prevents overheating, ensuring stable operation for extended hours, which is essential for industrial production lines.

3. STYLECNC’s UV laser markers support a wide range of materials, including plastics, glass, silicon, ceramics, and metals. This versatility makes them suitable for diverse industries like automotive, electronics, and packaging.

4. With a direct factory supply model, STYLECNC eliminates middlemen costs, providing affordable yet high-quality machines. Plus, their energy-efficient systems reduce operating expenses, making them a cost-effective investment.

5. STYLECNC provides comprehensive after-sales support, including installation guidance, training, and technical assistance. With a warranty on all machines, customers can invest with confidence, knowing they have reliable backup when needed.