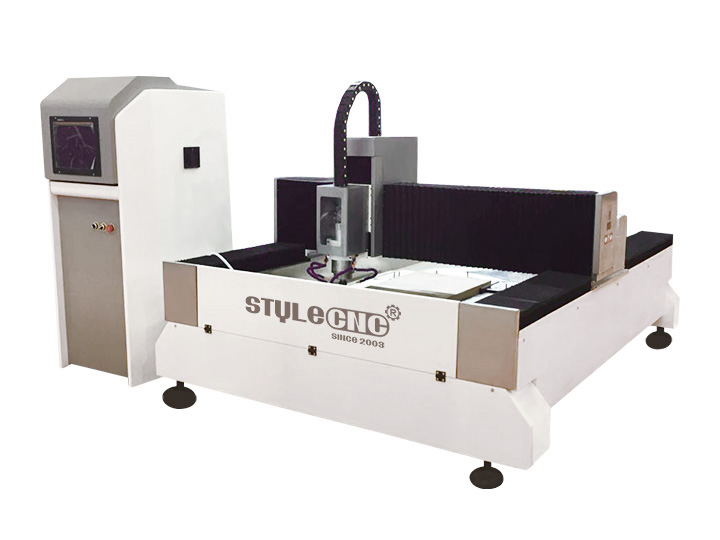

New design affordable stone CNC machine STS1318 is used for carving and cutting marble, granite, quartz, and other stones. Now the best CNC stone router machine for sale at low price.

New Design Stone CNC Machine is the latest development within high-precision material processing that pertains to marble, granite, and quartz among others. It is a technically advanced feature that entails complicated carving, cutting, and engraving; therefore, it has been considered an indispensable assistant in this line of industry. It's designed to manage complexities arising during stone processing, improved speeds, accuracy, and flexibility.

Equipped with a rigid frame and hard spindles, durability is accorded even in conditions of hard work. It utilizes computer numerical control to automate such operations, hence the ability for the operations to be more reproducible and consistent. From the different decorative stone works to the different intricate designs on countertops, the New Design Stone CNC Machine is made to answer varied demands in the stone industry. That is coupled with user-friendly software to make it easy to program the said work even for an operator without any high experience in using a CNC.

1. The stone CNC machine bed is welded by a thick wall steel seamless tube, high-temperature tempering treatment, high rigidity, and bearing strength better.

2. Dual stepper motor drive for Y-axis, moving stably.

3. DSP control with good software compatibility, suitable for Type3, Artcam, Castmate, and Ucanam.

4. Constant spindle motor 5.5 KW power, strong cutting strength, high efficiency.

5. High precision rack transmission, high speed.

6. Imported linear square guide way, double row 4 row slider, high precision, long lifetime.

7. Well-selected electrical accessory, let the failure rate to the minimum.

8. With water and automatic water supply and cooling system.

9. Dustproof and waterproof design, better to protect the machine driving part.

| Model | STS1318 |

| Working Area | 1300x1800x300mm |

| Table Size | 1450x2240mm |

| Traveling Positioning Accuracy | ±0.03/300mm |

| Reposition Accuracy | ±0.03mm |

| Table Surface | T-slot Table |

| Frame | Welded Structure |

| X, Y Structure | Rack and Pinion Drive, Hiwin Rail Linear Bearings |

| Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

| Max. Power Consumption | (Without Spindle) 3.0Kw |

| Max. Rapid Travel Rate | 33000mm/min |

| Max. Working Speed | 25000mm/min |

| Spindle Power | 5.5KW |

| Spindle Speed | 0-24000RPM |

| Drive Motors | Leadshine stepper motors |

| Working Voltage | AC380V/50/60Hz,3PH |

| Command Language | G Code |

| Operating System | NK105 DSP control system |

| Computer Interface | USB |

| Flash Memory | 128M(U Disk) |

| Collet | ER25 |

| X,Y Resolution | <0.03mm |

| Software Compatibility | Type3/UcancameV9 Software, (Option: Artcam Software) |

| Running Environment Temperature | 0 - 45 Centigrade |

| Relative Humidity | 30% - 75% |

| Packing Size | 3550X2300X1900mm |

| N.W. | 1600KG |

| G.W. | 1880KG |

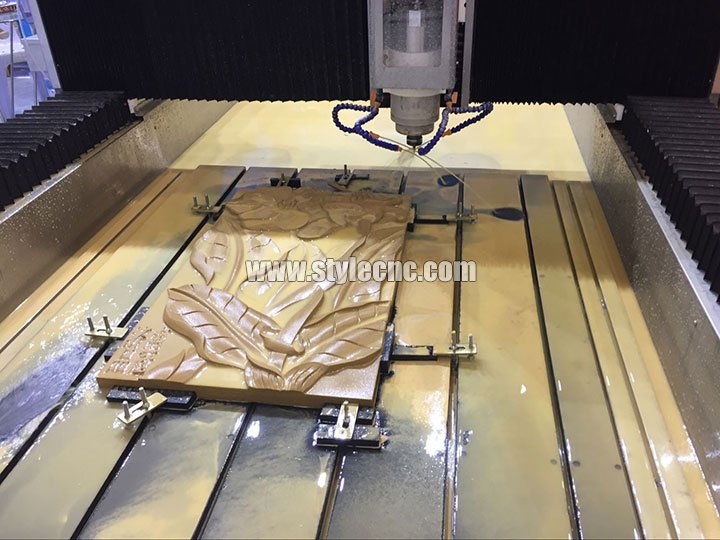

The New Design Stone CNC Machine enhances stone carving and cutting by offering increased precision, speed, and versatility, enabling the realization of detailed and intricate designs that were hard to achieve with traditional methods. This advanced technology enables the handling of tough materials like granite, marble, and quartz with powerful spindles and robust mechanics.

The machine has automated processes that eliminate human error and increase consistency. With the CNC control, the facilities for carving, cutting, and engraving become very precise; hence, it is ideal for bulk production and personalized designs. It also offers more flexibility in design complexity, enabling the operator to create fine details and shapes that may be complicated or time-consuming if done by hand.

Overall, the New Design Stone CNC Machine makes stone carving and cutting not only more efficient but of higher quality, with broader design possibilities and simplification of production in general for stone industries.

The stone CNC machine is used to create line engraving, 2D carving, 3D milling, 3D relief carving, cutting, drilling, and more.

Applicable Materials

Stone, marble, granite, black stone, bluestone, jade stone, crystal, glass, organic glass floor tile and ceramic tile, plastic, chemical synthesis board, PVC board, bamboo ware, aluminum plastic panel, metals.

Applicable Industry Representative Products

Stone Industry: Stone, ink-stone cutting, tombstone, jade, and marble products.

Kitchen Ware Industry: Man-made marble cabinet table surface.

Artwork Decoration Industry: Woodcrafts, gift boxes, jewelry boxes, and other exquisite art crafts.

Woodworking industry: Chair, doors, windows, beds, cabinets, kitchen wares, redwood classical and antique furniture, exquisite European furniture, decorative products sculpture.

Mold Industry: Engraving copper, aluminum, and other metal molds; Building models, shoes, badges, embossed mold, biscuits, candy, chocolate mold, artificial marble, plastic sheeting, PVC, wood, foam and other non-metallic mold.

Advertising Industry: Billboard, signage, badges, logo, company plates, signs, emblem, badge, display panels, fair signs, building numbers, signs of decoration, literal hole cutting, 3D character cutting, acrylic cutting, LED/Neon channel, light box.

Regular maintenance of Stone CNC Machines is vital for their durability, performance, and accuracy in carving, cutting, and engraving. A proper routine of regular maintenance prevents the breakdown of a machine and boosts the efficiency of the machine overall.

Regular Cleaning

Cleaning the machine after each use removes stone dust and debris from the work area. Ensure that all moving parts, especially the rails and spindles, are free from dirt to maintain smooth operation. Regular cleaning prevents clogging, which may affect the accuracy of cuts.

Lubricate Moving Parts

Periodic lubrication to the rails, spindles, and ball screws will prevent wear and tear. The lubricants used will be recommended as indicated in the machine's manual to optimize the performance of the machine while at the same time reducing friction. Proper lubrication can further prevent overheating and shutdowns of the machines.

Check Electrical Connections

At intervals, check for wear or damage to electrical connections, wiring, and cables. Malfunction or failure of a system could be caused by loose or damaged connections. Thus, this assures the reliability of the system, which prevents expensive repairs.

Spindle and Tooling Check

The spindle must be working right and the tools must be sharp. Worn out tools will affect the quality of the cut, plus they place additional loads on the machine that may not need it. Every cut gets its precision and quality when the tools are replaced or sharpened.

Cooling Systems

The cooling systems, either water or air cooling, must be working well to prevent overheating of the spindle. The cooling system must be cleaned regularly to prevent clogging and debris buildup, keeping the system running at the best temperatures without thermal damage to the components.

Perform Software Updates

Always update the CNC machine software for its latest features, bug fixes, and improvements on operation. Make sure to always backup important files before updating. Software updates guarantee a smooth-running and compatible tool for new materials and tools.

The new design Stone CNC Machine brings advanced features and unparalleled efficiency, thus proving to be a worthy investment in businesses dealing with stone carving and cutting. Here is why it stands out.

Enhanced Precision and Quality

The new design boasts cutting-edge technology in cutting and carving, providing unparalleled precision. It ensures that even the most intricate designs are executed with remarkable detail, hence making it suitable for producing quality products.

Versatility Across Materials

This machine will work on a wide array of materials, including marble, granite, quartz, and other types of stones. Its versatility will enable businesses to answer varied customer needs, from kitchen countertops to artistic engravings.

Improved Speed and Efficiency

The new design offers faster processing times and optimized tooling capability, thus reducing production time significantly. This helps a business complete projects faster without necessarily compromising on quality.

User-Friendly Operation

The intuitive interface and automated functions in the machine make it accessible to operators with even minimal experience. Its ease of use reduces training time and minimizes operational errors.

Durable Construction

It is made with strong materials and designed for heavy-duty applications; the machine is thus capable of handling high workloads. This durability ensures longevity, thereby guaranteeing reliable performance even in demanding environments.

Cost-Effective Investment

From the combination of high performance and low maintenance requirements, this CNC machine offers great value. It minimizes operational costs while maximizing output, hence being a wise choice for business growth.

Customizable Features

The new design enables special configurations to meet particular business needs. Be it special tooling or further software integrations, the flexibility makes it suitable for a variety of applications.

This is my second CNC machine from STYLECNC. The first one is still working like a champ. Really well designed, sturdy, easy to operate. Saved me time and probably money.