What is a 5x10 CNC Stone Carving Machine?

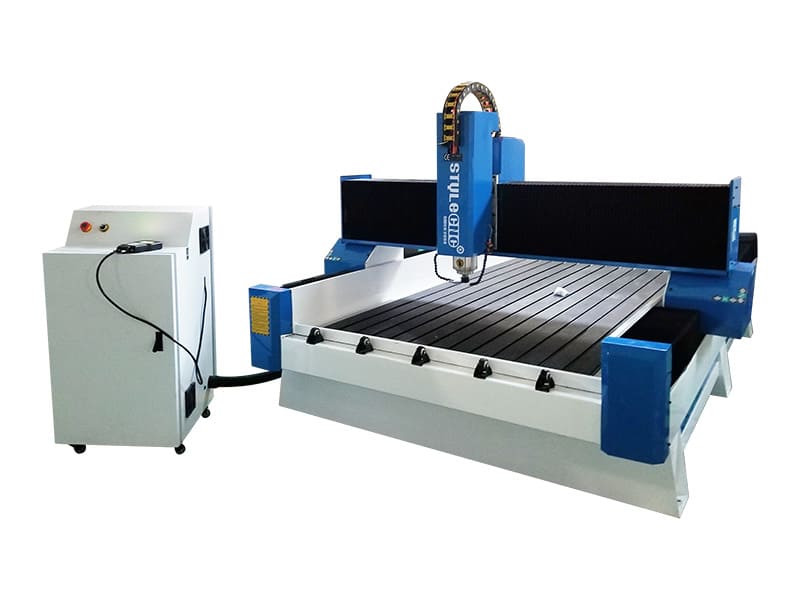

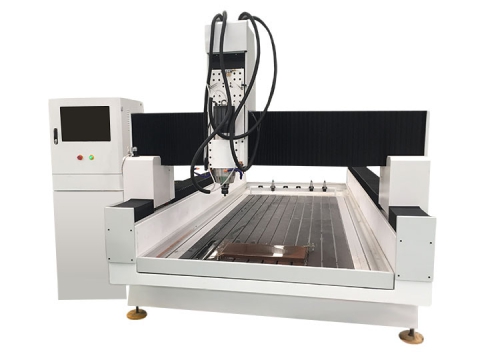

A 5x10 CNC stone carving machine is a specialized, computer-controlled device that cuts, engraves, and shapes stone. Its extra-large 5x10-foot bed size lets it handle large slabs of stone, ideal for architectural and industrial applications. Such a precision, automated machine can create intricate designs on hard-surface stones like granite, marble, and others.

It involves high-speed routers for engraving, milling, and carving, with the ability to do detailed work. One can program it for multiple tasks to get the same consistency in each project. Software available for its use allows one to have complex patterns and 3D design versatility for both decorative and functional works of stone.

From monuments down to custom countertops, the 5x10 CNC stone carver proves to be highly valuable. It's just what a company needs to take full leverage on its production process in a very effective way regarding efficiency, precision, and consistency.

2025 Best 5x10 CNC Stone Carving Machine Applications

Stone Industry: Stone, ink-stone cutting, tombstone, jade, and marble products.

Kitchen Ware Industry: Man-made marble cabinet table surface.

Artwork Decoration Industry: Woodcrafts, gift boxes, jewelry boxes, and other exquisite art crafts.

Woodworking industry: Chair, doors, windows, beds, cabinets, kitchenware, and other furniture; Redwood classical and antique furniture, Exquisite European furniture, decorative products sculpture.

Mold Industry: Engraving copper, aluminum, and other metal molds; Building models, shoes, badges, embossed mold, biscuits, candy, and chocolate mold; Artificial marble, plastic sheeting, PVC, wood, foam, and other non-metallic mold.

Advertising Industry: Billboard, signage, badges, logo, company plate, signs, emblem, badges, display panels, fair signs, building numbers, signs of decoration, literal hole cutting, 3D character cutting, acrylic cutting, LED/neon channel, and lightbox making.

Technical Parameters of 5x10 CNC Stone Carving Machine

| Model | STS1530 |

| Working Area | 1500x3000x300mm |

| Table Size | 1560×3340mm |

| Traveling Positioning Accuracy | ±0.03/300mm |

| Repositioning Accuracy | ±0.03mm |

| Frame | Welded Structure |

| X, Y Structure | Rack and Pinion Drive, Hiwin Rail Linear Bearings |

| Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

| Max Carving Speed | 3000mm/min |

| Spindle Power | 5.5KW |

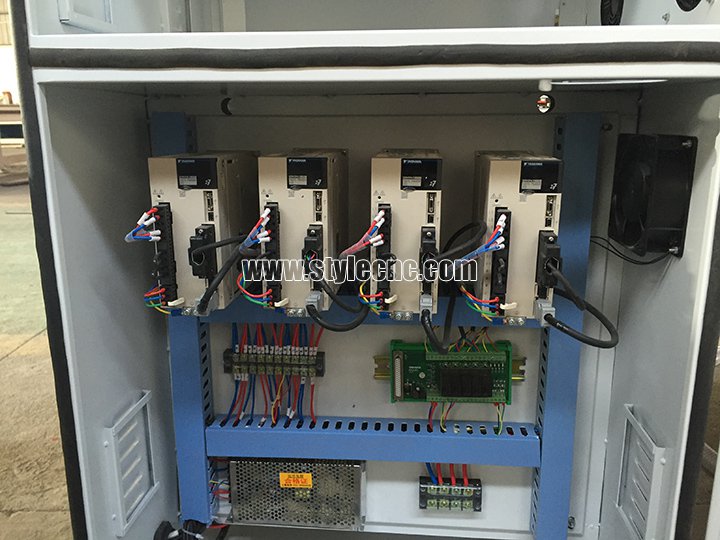

| Drive Motors | Yaskwa servo system |

| Working Voltage | AC380V/50/60Hz,3PH (Option: 220V) |

| Command Language | G Code |

| Operating System | NC studio control system |

| Computer Interface | USB |

| Flash Memory | 128M(U Disk) |

| X,Y Resolution | <0.03mm |

| Software Compatibility | Type3/UcancameV9 Software (Option: Artcam software) |

| Running Environment Temperature | 0 - 45 Centigrade |

| Relative Humidity | 30% - 75% |

Materials Compatible with the 5x10 CNC Stone Carver

The 5x10 CNC stone carving machine is highly versatile and capable of working with various stone types. Its adaptability to different materials makes it ideal for businesses involved in diverse stone projects.

Granite, Marble, and Quartz

Granite, marble, and quartz probably hold the number one position among stones used in CNC stone carving. These stones are hard and thus give excellent, lasting finishes. With the precision of a CNC, an artist would be able to engrave detailed patterns, cut out custom shapes, or make complex designs without having to sacrifice the integrity of the material.

Limestone, Slate, and Sandstone

Limestone, slate, and sandstone are more natural in appearance and softer, thus easier to engrave, than harder stones. This can enable intricate engravings and patterns on such softer stones for more ambitious architectural and decorative projects such as cladding, fireplaces, and sculptures.

Onyx and Travertine

Onyx and travertine have unusually exquisite patterns; hence, they are valued in creating applications requiring high-end values. Gentle and controlled actions by the CNC machine minimize chipping and cracking, retaining the integrity of delicate, translucent stones like onyx. The material application would be intended for high-end projects: inlays, backlit panels, inlaid tables, and decorative wall features.

Soapstone and Bluestone

Soapstone and bluestone are versatile options for intricate designs and carving. While they are soft and easy to shape, they still offer durability and a unique, natural appearance. These materials are popular for countertops, artistic carvings, and specialized architectural features, where the CNC machine allows precise, consistent cuts.

5x10 CNC Stone Carving Machine Features

1. The 5x10 CNC stone carving machine bed is welded by the thick wall steel seamless tube, high-temperature tempering treatment, high rigidity, and bearing strength better.

2. The 5x10 CNC stone carving machine adopts a dual Yaskawa servo motor drive for the Y-axis, moving stably with high speed.

3. High-power spindle motor with a direction water-cooling system, strong carving and cutting strength, and high efficiency.

4. Taiwan Hiwin linear square guide way, double row 4 row slider, high precision, long service life.

5. Dustproof and waterproof design, better to protect the machine driving part.

6. Auto oil lubrication to make the maintenance more easy.

7. Stainless steel water tank for stone carving.

2025 Best 5x10 CNC Stone Carving Machine Projects

Benefits of Choosing a 5x10 CNC Stone Carving Machine

A 5x10 CNC stone carving machine combines efficiency, accuracy, and flexibility, providing various advantages to meet business and creative demands.

Large Workspace for Big Projects

The expansive 5x10-foot worktable can accommodate large stone slabs, making it ideal for full-sized projects like countertops, wall panels, and monuments. This size reduces the need to reposition materials frequently, improving both speed and accuracy in production.

Precision and Detail

Equipped with advanced software, the machine delivers exceptional accuracy, making it easy to create intricate designs with consistent output. The precision ensures that each piece meets exact specifications, crucial for both custom projects and mass production.

Increased Production Efficiency

The machine’s automation allows for repeatable, consistent tasks without manual intervention. This streamlines operations and increases overall production rates, ideal for businesses handling multiple projects simultaneously.

Reduced Material Waste

With the machine’s precise control, there’s minimal material waste, making it cost-effective and environmentally friendly. It allows users to maximize each stone slab, improving profitability while reducing unnecessary waste.

Versatile Design Capabilities

The CNC stone carving machine’s software supports complex 3D designs, engraving, and detailed carvings. This versatility makes it suitable for diverse projects, from simple cuts to highly detailed artistic patterns.

Tips for Buying the Best 5x10 CNC Stone Carving Machine for Your Needs

Selecting the right CNC stone carving machine can greatly influence the quality, efficiency, and overall success of your projects. Here’s a guide to essential considerations.

• Evaluate Your Material Needs: Ensure the equipment you purchase will be capable of working with the specific types of stone you're going to be working with. Some machines work better on hard stones like granite, while others are best for engraving soft stones like limestone.

• Machine Specifications: Check the spindle speed of the machine, power rating, and dimensions of the work table. The higher the spindle speed, the smoother the cuts; the more adequate the power, the easier it would be for the machine to carve through tough materials.

• Essential Features: Dust collection, water cooling system, and an efficient exhaust system keep the machine running for a long period with accuracy in cuts, and an addition to improve safety by keeping the work area free of debris.

• Software Compatibility: The software used in the machine should be compatible with one of the more common CAD or design applications. Compatibility with standard file formats, like DXF or STL, gives more flexibility in design and workflow, thus allowing direct project transfers to the machine.

• Maintenance and Support: Discuss the maintenance of the machine and its after-sales support. How easy is the technical support, spare parts, or counsel to access? Optimum performance is ensured when easy access to such services is available.

• Budget and Return on Investment: Ponder upon the cost of the machine against ROI. For instance, a marginally higher upfront price might be justified if it includes features that lower operating costs or enhance productivity.

• Study User Testimonials and Reviews: Research some user reviews or testimonials to understand the reliability of the machine, ease of use, and quality. You will most likely get several firsthand reports about its real-world performance and longevity, which will help you make your decision with due diligence.