Most custom kitchen countertops and vanity countertops are made of marble, granite, quartz, rock slabs, and ceramic tiles because they are corrosion-resistant, pollution-resistant, high-temperature resistant, impact-resistant, waterproof, easy to clean, beautiful, and durable.

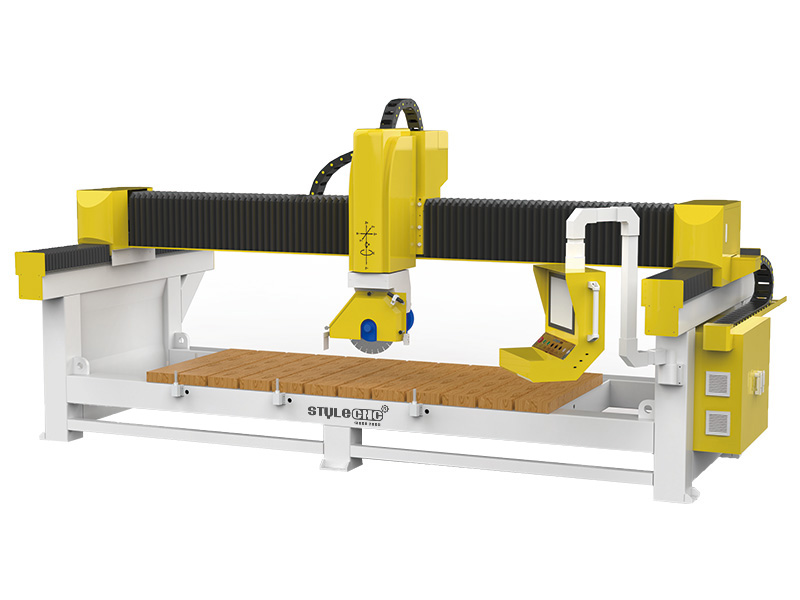

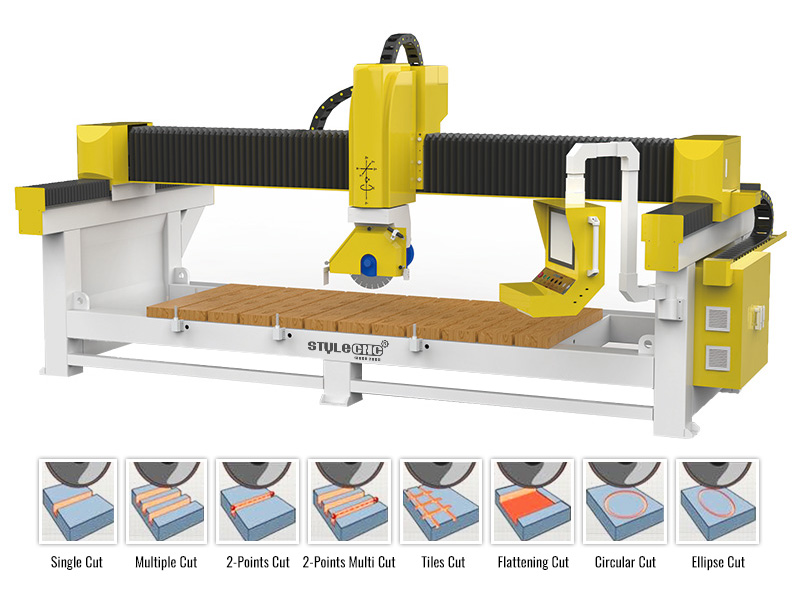

Decoration workers usually use portable masonry saws to cut personalized countertops. But the speed is slow with low precision, and the stone dust is easy to cause environmental pollution. Later, some stone workers chose CNC router machines to cut countertops. Although the precision was higher, the speed was too slow, even inferior to handheld masonry saws. In this case, a new type of smart automatic stone-cutting tool came into being. It is the CNC bridge saw, including 2 common types of 4-axis and 5-axis. The following is the 4-axis bridge saw with infrared positioning for automatic stone cutting.

4-axis bridge saw stone cutting machine integrates horizontal cutting, vertical cutting, 45-degree oblique cutting, round, oval, special-shaped layout, infrared positioning, CNC automation, and other functions. It is used to cut quartz, granite, marble, rock slabs, ceramic tile, slate, and other stone materials. It aims to solve the problem of time-consuming, labor-intensive, and high-cost high-end technology in the production process of stone countertops.

Technical Parameters of 4 Axis CNC Bridge Saw for Kitchen Countertops & Vanity Tops

| Brand | STYLECNC |

| Model | ST3220S | ST3012S |

| Table Size | 3200*2000*400mm | 3000*1200*400mm |

| Blade Rotation Degree (C Axis) | 0°-360° |

|

| Blade Tilting (A Axis) | 45° |

|

| Blade Diameter | Φ350-Φ400 |

|

| Power of Saw Motor | 13KW |

|

| Rotation Speed of Saw Motor | 0-6000rpm/min |

|

| Drive Motor | Taiwan 1.5KW Servo Motor |

|

| Workbench Tilting Degree | 0-85° |

|

| Total Power | 20.5KW |

|

| Water consumption | 3.5m³/h |

|

| Dimension | 5360*3225*2410 mm | 5080*2390*2320mm |

| Weight | 4500KGS | 4000KGS |

| Transport | 20GP | 20GP or LCL |

Features of 4 Axis CNC Bridge Saw for Kitchen Countertops & Vanity Tops

• Full 3D design and stress analysis, all the accessories used are excellent, after tempering, they are machined by high-precision CNC machines to ensure overall accuracy.

• The bed body and gantry structure are welded with high-quality steel as a whole and are tempered to ensure that the machine will not produce stress deformation for long-term use.

• Taiwan high-precision ball-screw and HIWIN guide rails, the oil-immersed lubrication method used in X and Y axes, the effective waterproof and dust-proof structure ensure high precision processing and maximize the service life of the ball-screw and guide rail.

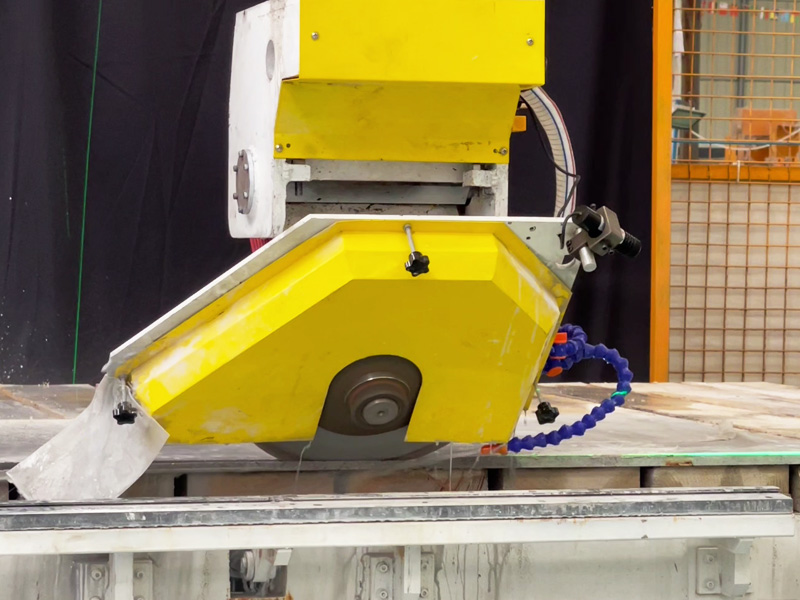

• Cutting head rotate 90°, tilting 45° suitable for chamfering cutting.

• The worktable is installed independently for tilting vertically at 85°, easier and safer to load raw materials.

• By infrared ray to confirm the position of the workpiece.

Motor Head

Infrared Ray Sensor

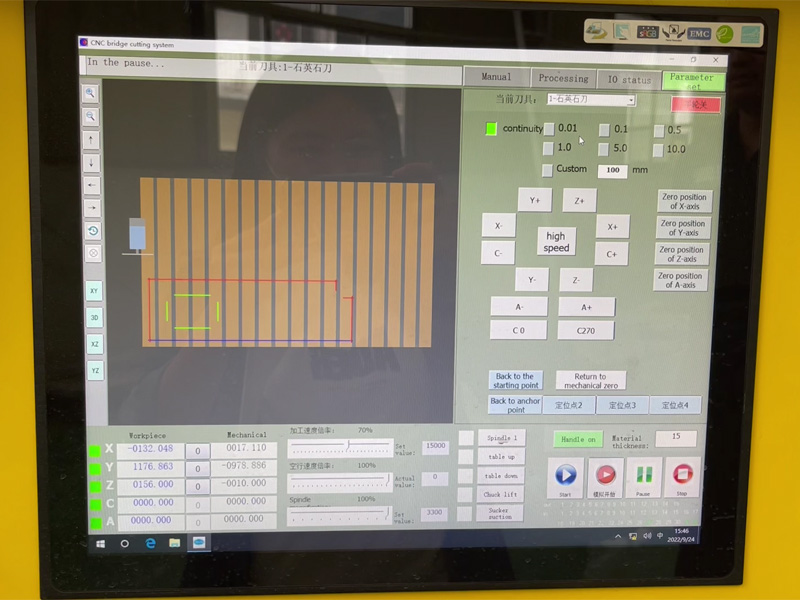

CNC Controller

Pros & Advantages of 4 Axis CNC Bridge Saw for Kitchen Countertops & Vanity Tops

The 4-axis CNC Bridge Saw is a game-changer for fabricators working on kitchen countertops and vanity tops. With its advanced features, it offers unmatched efficiency and precision, delivering professional-quality results in less time. Here are the key advantages of this powerful tool:

• Automation for Enhanced Efficiency: The machine’s fully automated process reduces the need for manual labor, streamlining production. This increases efficiency and reduces human errors, making it a cost-effective solution for fabricators.

• Dust-Free Operation for a Cleaner Environment: The system is designed to create a dust-free workspace, protecting both the workers' health and the quality of the materials being worked on. This feature is crucial for improving air quality and maintaining a cleaner shop floor.

• Intelligent Control System with CAM Software: The 4 Axis CNC Bridge Saw is equipped with a professional control system that integrates with built-in CAM software. This system recognizes CAD drawings and allows for easy customization of designs, reducing time and errors in the production process.

• Precise and Accurate Cuts: Thanks to its advanced technology, the 4 Axis CNC Bridge Saw provides highly accurate and smooth cuts, ensuring that each countertop or vanity top is perfectly shaped and sized to meet customer specifications.

• User-Friendly Operation: The customized control system is intuitive and easy to learn, making it accessible to operators with varying levels of experience. This helps businesses save time on training and enables faster adoption of the system.

Applications of 4 Axis CNC Bridge Saw for Kitchen Countertops & Vanity Tops

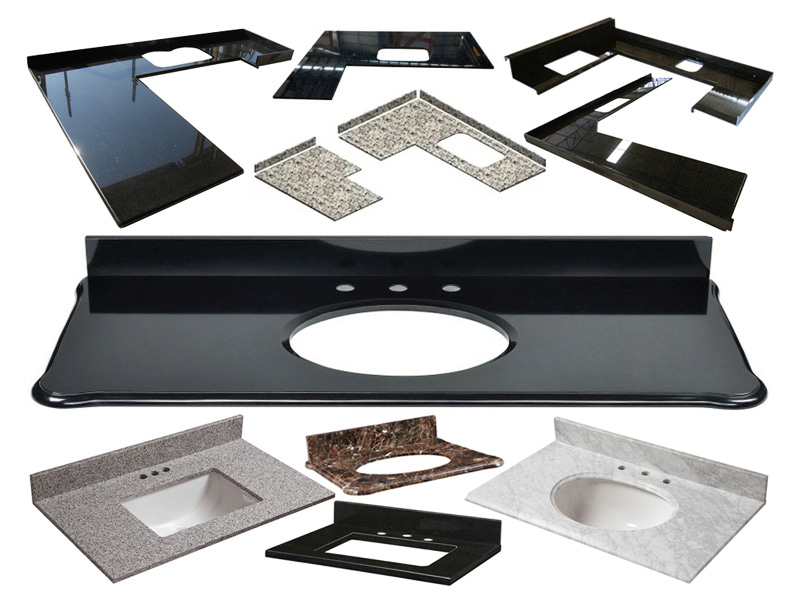

The 4-axis CNC Bridge Saw is highly versatile, making it perfect for a range of stone-cutting applications. Whether you're working on kitchen countertops, bathroom vanity tops, or other surfaces, this machine ensures high-quality, precise results every time. Here are its key applications:

• Kitchen Countertops: The machine’s precision makes it perfect for cutting and shaping granite, marble, and quartz kitchen countertops. It can handle both large and intricate designs with ease, ensuring top-quality results for customers.

• Bathroom Vanity Tops: The saw’s accuracy is ideal for creating vanity tops with perfect edges and smooth finishes. It is a popular choice for fabricators looking to create high-quality stone countertops for bathroom applications.

• Bar Island Counters: Whether you’re working with granite or marble, the 4 Axis CNC Bridge Saw can craft intricate and unique designs for bar island counters that enhance the aesthetic of any space.

• Coffee Table Surfaces: The machine is ideal for cutting and shaping stone tabletops for coffee tables. It ensures each piece is cut to size with precision, offering a smooth, professional finish.

• Stone Tabletops: Perfect for cutting tabletops in various styles, from traditional to modern. The saw provides precise measurements, ensuring the design fits the intended space perfectly.

• Architectural Stonework: Beyond countertops, this machine can be used for cutting and shaping architectural stone for various other applications, providing the same level of precision and quality for all projects.

Exploring the Versatility of 4-Axis CNC Bridge Saw in Other Industries

The 4-axis CNC Bridge Saw is a versatile tool that’s not just limited to kitchen countertops and vanity tops. Its cutting-edge technology and precision make it suitable for a variety of industries. Let’s take a closer look at how this machine is transforming other sectors beyond stonework.

1. Stone Art and Sculptures

The 4-axis CNC Bridge Saw is widely used in the creation of intricate stone art and sculptures. Artists and craftsmen can now achieve detailed designs in marble, granite, and other types of stone with precision. The machine's advanced capabilities allow for fine-tuned control over each cut, ensuring the highest quality artistry.

2. Flooring and Tiling

In flooring and tiling applications, this machine is perfect for cutting large stone slabs into tiles for floors, walls, and decorative surfaces. Its accuracy makes it easy to achieve perfect tile shapes and sizes, improving the quality of the final product and reducing the chances of waste.

3. Custom Furniture Design

Furniture makers in the luxury market are using the 4-axis CNC Bridge Saw to create custom, high-end stone furniture. This includes items like stone tabletops, countertops, and even decorative panels. The precision of the machine helps in making unique and intricate designs, giving furniture manufacturers a competitive edge.

4. Exterior Facades and Cladding

In the construction industry, the 4-axis CNC Bridge Saw plays a crucial role in the cutting and shaping of stone materials for building facades and cladding. Architects use the machine to achieve custom patterns and precise cuts for both aesthetic and functional purposes. This enhances the durability and appearance of the exterior of buildings.

5. Monuments and Memorials

For manufacturers of monuments, gravestones, and memorials, the 4-axis CNC Bridge Saw is a vital tool. Its precision allows for the production of detailed engravings and custom shapes in stones used for memorial purposes. The machine helps artisans create personalized and high-quality memorials for clients.

6. Engineering and Aerospace

In the engineering and aerospace industries, the 4-axis CNC Bridge Saw is used to cut composite materials and metals. Its high precision makes it ideal for creating parts for aerospace components, ensuring every piece fits perfectly within complex structures.

4 Axis CNC Bridge Saw for Kitchen Countertops & Vanity Tops Projects

How to Maintain Your 4-Axis CNC Bridge Saw for Maximum Longevity

Proper maintenance of your 4-axis CNC Bridge Saw is essential to keep it performing at its best and ensure its longevity. By following a few simple steps, you can prevent breakdowns, minimize costly repairs, and extend the life of the machine.

• Regular Cleaning and Dust Removal: Clean the saw frequently, especially around the cutting area, to remove dust and debris. Use compressed air or a vacuum to keep components like rails and the spindle clean.

• Lubrication of Moving Parts: Lubricate moving parts like the rails, gears, and spindles to ensure smooth operation and reduce friction. Always use the recommended lubricants to maintain the machine's efficiency.

• Check and Replace Worn Parts: Inspect parts like saw blades, motors, and bearings regularly. Replace any worn-out components to avoid further damage and ensure the machine continues to operate smoothly.

• Software and Calibration Updates: Regularly update the software and perform calibration checks to ensure the machine operates with precision. Proper calibration helps maintain accuracy and efficiency over time.

• Proper Training for Operators: Ensure operators are well-trained on how to use the machine properly. Proper handling minimizes the risk of errors and reduces wear and tear, extending the life of your CNC Bridge Saw.