2024 Cheapest Fiber Laser Cutter for Cutting Sheet Metals

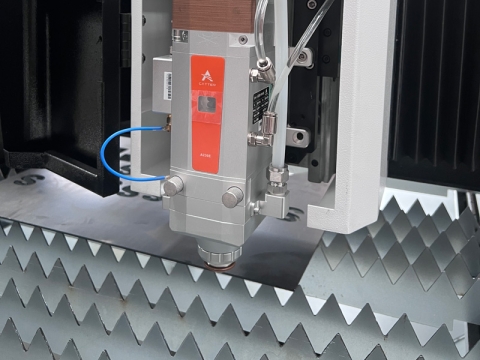

This video showcases the best and most affordable fiber laser cutting machine ST-FC3015E for sheet metal fabrication with power options from 1000W to 3000W.

You will review how does a high definition CNC plasma cutter table cut and drill holes on sheet metal in this video. This high precision CNC plasma cutting machine is equipped with a plasma cutting head for thin metals cutting, a drilling head to drill holes on metal, a flame torch for oxy-fuel cutting carbon steel, low alloy steels, and cast irons with more thickness.

High definition CNC plasma cutting machine is an efficient automatic metal cutting equipment. Its working principle is to use compressed air as the ionizing medium, and use the compression of the cutting gun nozzle to form a high-density plasma arc heat source to melt the metal, and at the same time use a high-speed airflow to blow away the melted metal to form a narrow slit, and metal is quickly melted and cut.

The frame of the high precision CNC plasma table adopts a fully welded structure, and the internal stress is eliminated by the effective vibration processor, so that the stability of the frame is improved and the amount of degeneration is small. The X-axis adopts high-precision linear circular guide rails, and the Y-axis adopts high-precision linear guide rails, so the running resistance is small. The X-axis and Y-axis are installed with multifunctional instruments for detection and installation. The straightness error of the 2 rails of the X-axis is guaranteed to be less than ±0.05mm, and the vertical error of the X-axis and Y-axis is not more than ±0.05mm. The running trolley adopts a lightw8 structure, which is convenient to ensure the quality of plasma cutting. The performance of the industrial computer operating system is stable and has a better man-machine dialogue interface. The industrial control computer can interface with ISO standard CNC language, which can display cutting graphics, simulate cutting, and has manual programming functions. The drive transmission system adopts a digital AC servo system. The motor adopts high-magnetic rare earth materials, has good magnetic conductivity and heat dissipation, and its code has a high resolution, thereby ensuring higher cutting accuracy. The software for the high precision CNC plasma cutting table is simple and easy to learn, flexible operation and high cutting accuracy.

This video showcases the best and most affordable fiber laser cutting machine ST-FC3015E for sheet metal fabrication with power options from 1000W to 3000W.

CNC plasma cutter with rotary device besides the plasma cutting table can cut sheet metals, square and round metal tubes to realize multi-functional cutting.

How to choose a CNC plasma cutting machine for metal fabrication? You need to consider the cutting quality, speed, thickness, table size, service & support.