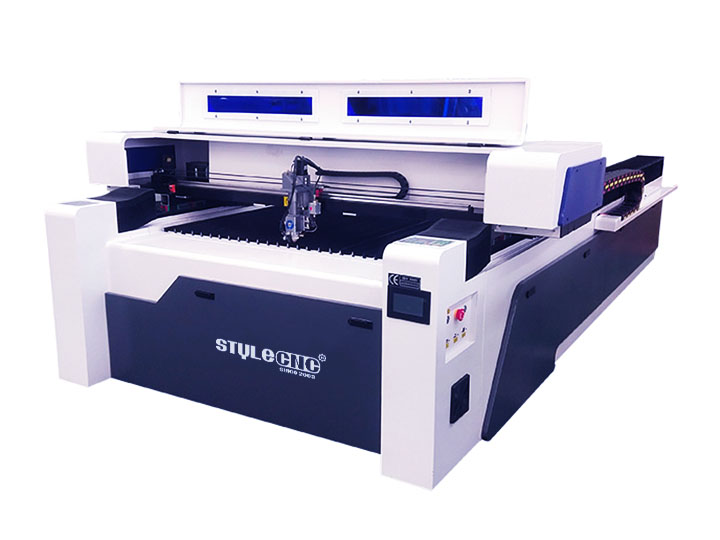

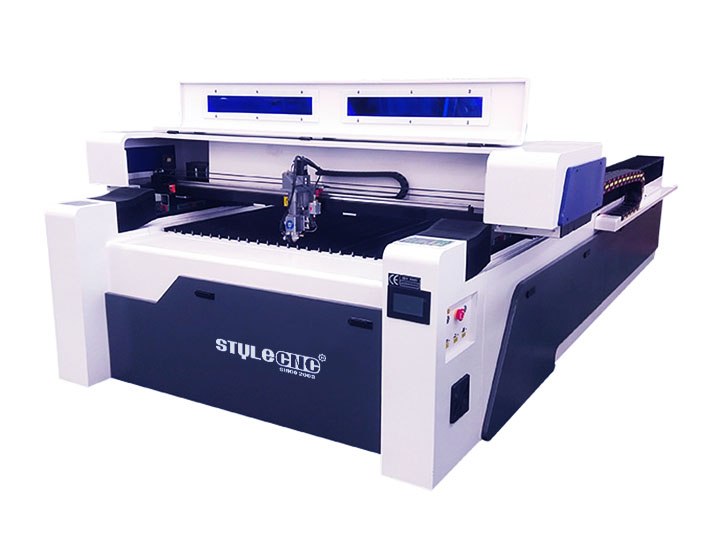

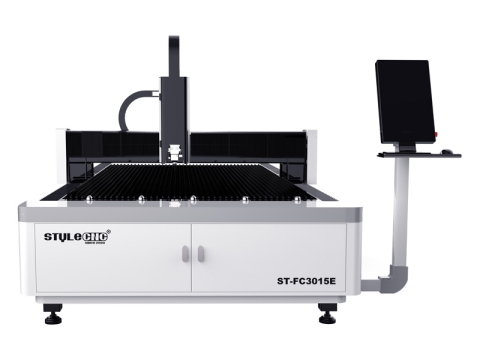

Mixed CNC laser cutting and engraving machines are different from ordinary CO2 laser machines and can cut and engrave both non-metallic materials and thin metals. All the machine parts and controllers adopt original parts with a long lifetime without deformation.

Mixed CNC Laser Cutter Engraving Machine Features

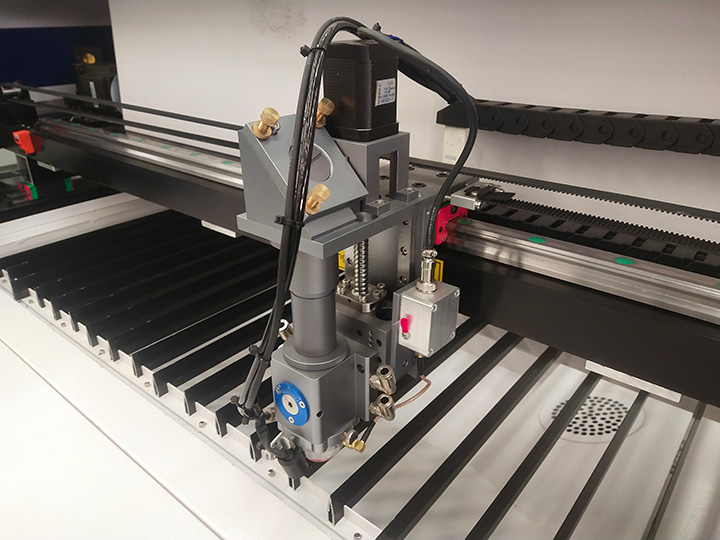

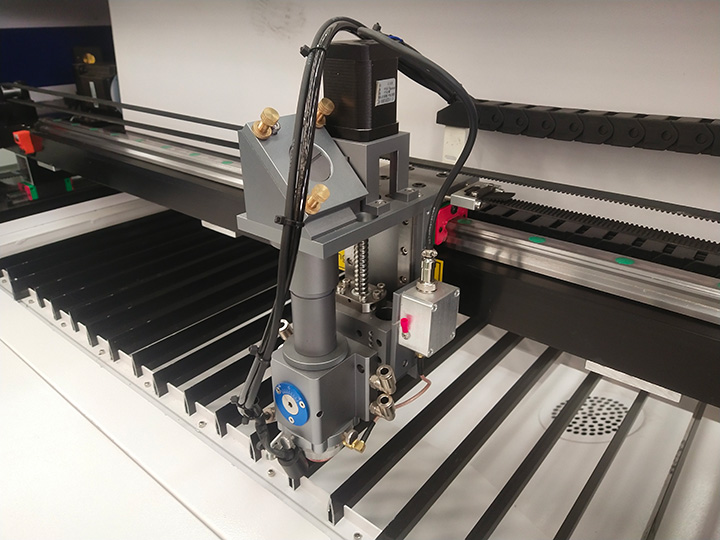

1. Mixed metal and non-metal laser cutting head with automatic sensor.

The STJ1325M can detect the surface of the metal materials and adjust the laser head automatically. If the thin metal materials are not flat, the laser head can move with it up and down.

2. Advanced RD control system with a colorful screen display and USB interface.

Dynamic display of the working process during machine cutting work. You can change the parameter on the panel.

3. USA imported a focus lens with a good reflective effect.

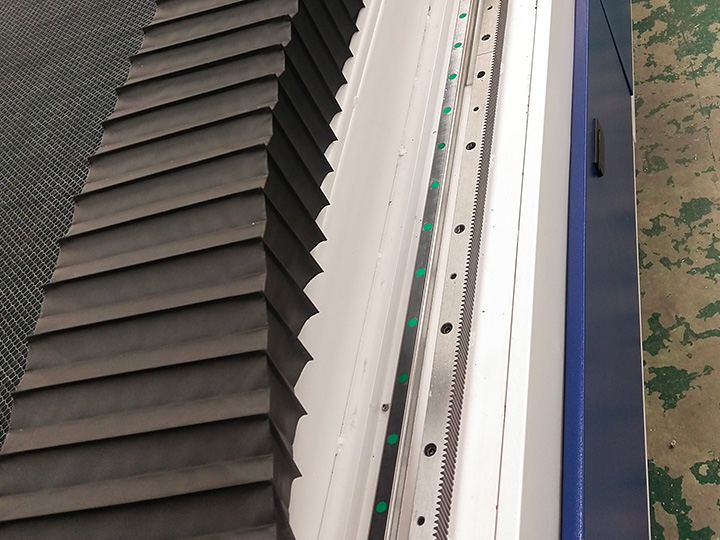

4. A whole set of imported guide rails from Taiwan. The Stepper motor with the driver is more powerful and accurate. Japan Yaskawa servo motor for choice.

5. A strong crate package guarantees safety when shipping.

Benefits of Using Mixed CNC Laser Cutter Machines

Both metal and wood CNC laser cutter machines create a great deal of benefit for businesses and hobbyists. Laser technologies combine versatility and precision; as a result, they come in handy for a lot of materials and applications. These are some of the prime advantages accrued from using these machines.

• These machines can cut and engrave both wood and metal with ease, making them ideal for a wide range of projects. Be it soft materials like wood or hard metals like aluminum, a mixed CNC laser cutter can handle both, saving time and costs associated with using multiple machines.

• CNC laser machines offer great accuracy that can provide fine, detailed cuts and engravings. This is very helpful for detailed designs and ensures quality on both wood and metal surfaces.

• With the capability to work on multiple materials, businesses and makers alike can simplify their processes. There's no need to switch between different machines for different materials, reducing downtime and overall production costs.

• Laser cutting is a very effective process; it makes clean cuts with minimal waste of material. This is pretty helpful in working with expensive metals or rare wood types because one can use almost every available piece of material effectively.

• Mixed CNC laser cutter machines allow endless possibilities of personalization. From personal wood items to engraved metal products, these machines allow creating custom designs that focus on special customer needs or creative projects.

• Many mixed CNC laser cutters come with easy-to-use software that simplifies the design process, allowing even beginners to get started quickly. This reduces the learning curve and makes the machines accessible to a broader range of users.

Mixed CNC Laser Cutter Engraving Machine Applications

A mixed CNC laser engraver cutting machine is used to engrave and cut thicker non-metal materials such as wood, plywood, MDF, acrylic, and die board, as well as thin sheet metals such as stainless steel, brass, copper, and aluminum. The features of this laser CNC cutter are perfect cutting effect and high cutting speed.

1. Advertising industry: Stainless steel. Acrylic plate. Color board and other advertising materials engraving and cutting.

2. Leather garment processing industry: Leather, fabric carve or hollow out patterns.

3. Arts and crafts industry: Paper cutting, wood, bamboo, leather, shell, ivory, and other materials engraving and cutting.

4. Modeling industry: Aviation and maritime models, wooden toys engraving, or cutting.

5. Packaging industry: Rubber printing plate engraving and cutting, bilayer plate, dye board cutting, etc.

6. Decoration industries: Electrical and electronic industry materials engraving and cutting.

Mixed CNC Laser Cutter Engraving Machine Technical Parameters

| TYPE | STJ1325M |

| Working Area | 1300mm(W)*2500mm(L) |

| Laser Power | 80W, 150W, 180W, 220W, 300W |

| Laser Type | Sealed CO2 Laser Tube |

| Cutting Depth (recommended) | Max. 30mm Acrylic / 2mm Steel / 20mm Die Board / 15mm MDF / 15mm Wood |

| Max. Cutting Speed | 0-200mm/s |

| Resetting Positioning Accuracy | ≤0.01mm |

| Lifespan of Laser Tube | Max. 10000 Hours |

| Maximum Forming Character | English letter: 1.5 x 1.5mm |

| Power Supply | 220V±10% 50HZ or 110V±10% 60HZ |

| Software Supported | ArtCut, CorelDraw, PhotoShop, AutoCAD |

| Graphic Format Supported | PLT, DXF, BMP, JPG, GIF, PGN, TIF, etc. |

| Transmission | X and Y axes with Ball Screws |

| X and Y axes with Linear Guide Rail |

| Drive Type | Step motor/Servo Motors |

| Interface | USB |

| CO2 Laser Tube | Yes |

| Air Compressor and Exhaust Fan | Yes |

| Water Chiller | Yes |

| Software authorized | RDworks |

| Water-cooling System for tube | Yes |

Mixed CNC Laser Cutter Engraving Machine for Wood & Metal Projects

Mixed CNC Laser Cutter Engraving Machine Package and Delivery

How to Choose the Right Mixed CNC Laser Cutter

Choosing the right mixed CNC laser cutter machine is important to keep your projects running smoothly and efficiently. While there's a huge variety, what you really need to look at are the key areas that suit your needs best. Here's a small guide on how to do just that:

Consider the Materials You'll Be Working With

Different laser cutters have different ways of handling various materials. You should search for a machine that will work effectively to cut and engrave the type of wood and metal you will be using. Ensure that the power and capability of the laser match your requirements.

Assess the Size of the Cutting Area

The size of the cutting bed is important, especially if you work with larger projects. Make sure the machine has enough space to accommodate the dimensions of your materials and designs, whether you're cutting large metal sheets or intricate wooden patterns.

Check the Laser Power

Laser power determines the efficiency of the machine in cutting various materials. High-power lasers are required for metals, while low-power lasers might be enough for wood and softer materials. For flexibility, choose a machine that has variable power levels.

Look for Precision and Accuracy

Precision is crucial for high detail and quality in designs. Verify that the CNC laser cutter features a high degree of accuracy with repeatability, which will be important, mainly if your work involves fine cuts or engravings on wood or metal.

Software Compatibility and Ease of Use

The right software can save your life. Your perfect machine should be compatible with popular design software and should provide an easy interface even for beginners. User-friendly software will save time and increase productivity.

The Quality of the Machine's Build

Invest in a durable, well-built machine that will deliver long-term performance and dependability. Assess the machine based on construction materials and reviews as a way to judge quality and longevity.

Consider Maintenance and Support

Choose a machine that features reliable customer support and ease of maintenance. Servicing will be required regularly to ensure your CNC laser cutter keeps working at its best, so manufacturers with strong after-sales service and parts availability are favorable.

Maintenance Tips for Mixed CNC Laser Cutter Machines

To ensure that your mixed CNC laser cutter machine lasts for many years, runs smoothly, and produces work accurately, you need to perform routine maintenance. Regular maintenance prevents breakdowns that stop work and reduces the quality of work. Here are some important tips for maintaining your machine at its optimum:

• Clean the Machine Regularly: Dust and debris can affect the performance of your CNC laser cutter. Cleaning should be done regularly on the cutting bed, laser head, and other parts with appropriate tools like soft brushes and air compressors. The machine should be free from material residue to avoid malfunctioning.

• Inspect and Replace the Laser Lens and Mirrors: These are the most crucial components in the process of laser cutting. With time, there will be a build-up of residues or even damage. Cleaning from time to time, inspect for dirt or any cracks, and replace if need be to ensure peak cut performance.

• Lubricate Moving Parts: Moving parts in a CNC laser cutter include rails and bearings, all of which should be duly lubricated. Manufacturer-recommended lubricants minimize friction while allowing smooth movement, thus not wearing out the machine components.

• Check and Calibrate the Machine: Regular calibration of the machine ensures that it cuts accurately. Verify the alignment of the laser and the cutting bed to make sure the machine performs consistently and provides precise results.

• Cooling System Monitoring: During the operation of the laser-cutting process, heat is produced; thus, maintenance of the cooling system is paramount. The regular checking of leakages and cleaning of the cooling system prevent overheating, which can damage laser components.

• Electrical Components Inspection: Check for wear or fraying of the electrical system and wiring. Electrical issues have to be handled in time because such problems will lead to the failure of a system.

• Perform Software Update: Keep updating the software to make it compatible with latest features and enhance overall performance of the machine.