STJ9060 hobby laser engraver with 2x3 table top is used to cut, engrave, and etch plastic, acrylic, glass, rubber, polymer, wood for hobbyists, small business, and home shop. Now the affordable 2x3 hobby laser engraving machine for sale at cost price.

Do you have DIY hobby laser engraver kit plans or need to buy an affordable hobby laser engraving machine for plastic, acrylic, glass, rubber, polymer, wood, metal, plywood, cardboard, die board, chipboard, fabric, textile, leather, paper, foam, ABS, EPM, MDF, PE, PES, PUR, PVB, PVC, PUR, PMMA or PTFE? Review the 2025 new hobby laser engraver buying guide as follows, we'll offer you 2025 best hobby laser engraving machines with custom hobby laser engraving service to fit your 2D/3D laser engraving projects, ideas, and plans.

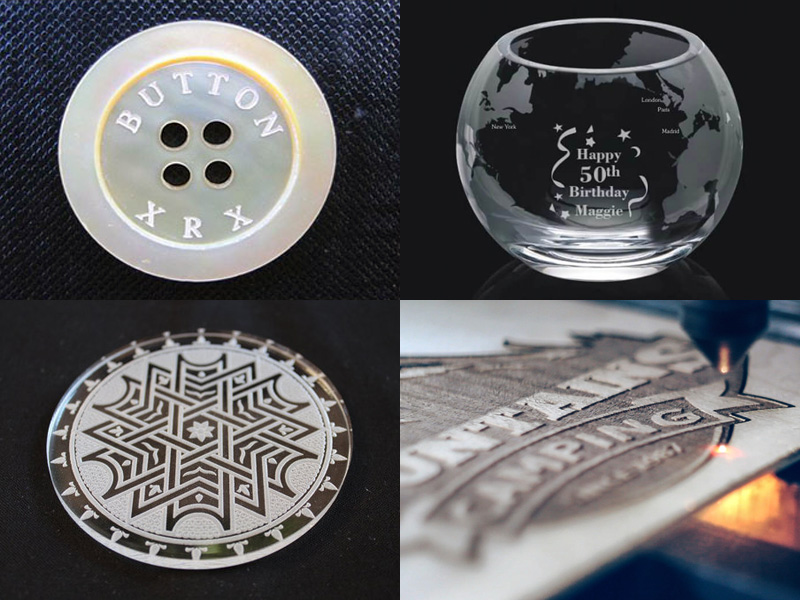

This type of hobby laser engraver comes with a CO2 laser tube, which is used to engrave and cut signs, letters, logos, numbers, and patterns on acrylic, PVC, rubber sheet, plastic, crystal, glass, wood, fabric, bamboo, ox horn, figuline, marble, leather, jeans, cloth, double-color board, and more nonmetal materials. It is also known as a laser plastic engraving machine, laser acrylic engraving machine, laser glass etching machine, laser rubber stamp machine, and laser polymer stippling machine.

A laser plastic engraving machine is a type of plastic laser engraver for etching letters, logos, signs, texts, patterns, or photos on Silicone, Polyamide (PA), Polyimide (PI), Polyester (PES), Polystyrene (PS), Polyethylene (PE), Polypropylene (PP), Polycarbonate (PC), Polyoxymethylene (POM), Poly ether ketone (PEEK), Polyarylsulfone (PSU, PPSU), Polymethylmetacrylate (PMMA), Polyethylene terephthalate (PET), Acrylonitrile butadiene styrene copolymer (ABS) to make custom plastic signs, plastic tags, plastic labels, plastic disc, plastic nameplates, and more plastic engraving projects & plans. It is also known as a laser plastic engraver, or laser plastic etching machine.

A laser acrylic engraving machine is a type of acrylic laser engraver for etching dates, numbers, letters, logos, patterns, photos, or prototyping on White Acrylic Sheets, Colored Acrylic Sheet, Clear Acrylic Sheet, Lucite Block Acrylic Sheet, Non-Glare Acrylic Sheet, Textured Acrylic Sheet, Mirrored Acrylic Sheet, Abrasion Resistant Acrylic Sheet, Anti-Static Acrylic Sheet, Light Diffusing Acrylic, Solar Tinted Acrylic, and Impact Modified Acrylic to make custom acrylic signs, acrylic keychain, acrylic light, acrylic plaques, acrylic blocks, acrylic photos, acrylic paint fill, acrylic invitations, and more acrylic engraving projects & plans. It is also known as a laser acrylic engraver or laser acrylic etching machine.

Laser rubber engraving machine is a type of rubber laser engraver for etching logos, numbers, letters, numbers, patterns, or prototyping on Natural Rubber (NR or Isoprene), Butyl Rubber (IIR), Styrene-Butadiene Rubber (SBR), Nitrile Rubber (NBR rubber or Buna-N), Ethylene Propylene Diene Monomer (EPDM Rubber), Neoprene Rubber (CR), Polyurethane Rubber (AU), Viton Rubber (FKM), Silicone Rubber (Q), and Hydrogenated Nitrile Rubber (HNBR) to make custom rubber stamps, silicon rubber bands, silicone rubber keypad, and more rubber engraving projects & plans. It is also known as a laser rubber engraver or laser rubber stamp machine.

A laser glass engraving machine is a type of glass laser engraver for etching signs, logos, numbers, letters, numbers, dates, patterns, photos, or prototyping on Float Glass, Toughened Glass, Tinted Glass, Obscured Glass, Laminated Glass, Mirrored Glass, Low E Glass, Coated Glass, Patterned & Decorative Glass, Wired Glass, Painted Glass to make personalized glass cubes, glass bottles, glass gifts, glass blocks, glass balls, glass trophies, glass awards, glass plaques, glass ornaments, and more glass engraving projects & plans. It is also known as a laser glass engraver or laser glass etching machine.

Laser polymer engraving machine is a type of polymer laser engraver for stippling names, dates, serial numbers, logos, patterns, or designs on natural polymeric materials (shellac, hemp, amber, wool, cellulose, silk) and synthetic polymers (polyethylene, polystyrene, polypropylene, polyacrylonitrile, nylon, synthetic rubber, polyvinyl chloride, bakelite, phenol formaldehyde resin, neoprene, silicone, PVB) to make polymer clay, polymer guns, firearms, weapons, polymer 80 and more polymer engraving projects & plans. It is also known as a laser polymer engraver or laser polymer stippling machine.

• Working Area: 900*600mm, which can be customized according to your requirements.

• Offline and online control system: A USB interface in the control panel, which has a line to connect the computer, supporting offline work, is more convenient.

• Knife worktable or Honeycomb worktable for option: Knife worktable is better for hard materials such as wood, acrylic, plastic, and glass. A honeycomb worktable is nice for soft materials such as leather, fabric, etc.

• High-resolution laser head: High quality and long lifetime.

• Water chiller: Cooling laser tube to protect it with a long life.

• Air pump: Cooling the laser head to prevent the materials from being burned.

• Exhaust fan: Blow away the smoke.

• Tool box: Including the CD, user manual, and some wrenches for your work.

| Model | STJ9060 |

| Working area | 900mm*600mm (2x3 feet) |

| Laser power | 60W - 100W |

| Laser type | CO2 sealed laser tube, water-cooled |

| Engraving speed | 0-6000cm/min |

| Cutting speed | 0-5000cm/min |

| Power supply | 220V/50HZ, 110V/60HZ |

| Graphic format supported | BMP, PLT, DST, DXF, AI |

| Software supported | CorelDraw, PhotoShop, AutoCAD, TAJIMA |

| Driving system | Stepper motor |

| Net Weight | 330kg |

| Optional parts | Up-down worktable, and rotary axis |

1. Water chiller: Cooling the laser tube. The water chiller cooling effect is much better than the water pump, it can extend the laser tube with a longer service life.

2. Up/Down table: Motorized up and down working table 200mm.

3. Rotary Device: Engraving on a cylinder, such as a cup, bottle, ball, tank pencils, pen, etc.

4. Air pump: Cooling the material when engraving and cutting. Blowing the fragments of material slit, so the laser machine can cut more thicker. Blowing the exhaust gas to protect the lens not dirty and destroy.

5. LCD control panel: Friendly LCD control panel in English, easy and convenient to operate. It has Start, Pause, Stop, Test, Datum, Laser, Menu, and Stop buttons. You can operate with these buttons. For example, moving the up and down working table, cutting, engraving, outlining, and others. Emergence stop can stop the laser machine immediately.

6. Exhaust fan:

• Remove the exhaust gas from the working area, because they are unhealthy and acrid.

• Blow the dust away, because if the dust is on the lens and mirrors, it will influence the effect of engraving and cutting.

7. Honeycomb table: It can also adsorb light materials, such as fabric, leather, and cloth, just like a vacuum.

8. Servo Motor and Stepping Motor:

The stepping motor is standard, Servo Motor is Optional, with a more accurate, fast speed/alarm function.

9. RECI laser tube (8000-10000 hours lifetime, 8-10 months warranty).

• Advertising industry: Organic glass cutting, signage engraving, double-color board engraving, crystal cup engraving, etc.

• Gifts industry: Engraving beautiful words and patterns on plastic, acrylic, wood, bamboo, marble, double-color boards, density boards, crystal, leather, etc.

• Packaging/printing industry: Engraving and cutting rubber plate, double layer plate, plastic plate.

• Leather/Garment processing industry: It can be used for a series of crafts processing complex graphics and characters, including engraving, cutting, stenciling, embroidery cutting, genuine leather, synthetic leather, artificial leather, and cloth.

• Other industries: It can be used for mold making, decorations, package engraving, and so on.

| Materials | Cutting | Engraving |

| Wood/Cork/Bamboo/Veneer/MDF | √ | √ |

| Acrylic/Rubber/Plexiglass/Pmma | √ | √ |

| Glass/Fiberglass | √ | |

| Mylar/Delrin/Matte Board | √ | √ |

| Fabric/Cloth/Textile/Garment | √ | √ |

| Leather/Pig leather/Cow leather/Sheep leather | √ | √ |

| Ceramic/Marble/Tile | √ | |

| Plastic | √ | √ |

| Melamine | √ | √ |

| Paper/Cardboard/Pressboard | √ | √ |

| Organic board / Double color plate | √ | √ |

| Corian | √ | √ |

Laser Stippling Polymer Glock Grip for Guns

Hobby Laser Engraver for Wood Box Engraving Cutting Projects

Hobby Laser Engraver for Glass Engraving Projects

Hobby Laser Engraver for Acrylic Engraving Cutting Projects

Laser Engraved Rubber Stamps

Hobby Laser Engraver for Plastic Engraving Cutting Projects

Hobby Laser Engraving Machine for Russian Dolls Projects

Fiber Laser Engraver for Plastic, Acrylic, Glass, Rubber, Polymer

UV Laser Marking Machine for Plastic, Acrylic, Glass, Rubber, Polymer

Laser engraving is fun and creative, but safety is always a priority. Even hobby-grade machines can produce heat and light far beyond anything that can be produced by an amateur, and failing to take proper care can lead to dangerous consequences. If you follow a few essential safety guidelines, there is no reason why you cannot achieve great results while also keeping your personal safety and the safety of your tools in mind.

Put On Essential Eye Protective Gear

The most effective way lasers can be described would be as focused beams of light that can be harmful if you are not careful, and protecting your vision is at the top of that list. Leave your regular sunglasses and transparent goggles at home because they won’t cut it, investing in certified laser protective eyewear will provide the necessary comfort and protection to let you operate freely. Be sure to always have laser protective glasses on hand that are appropriate for the specific wavelength of your equipment.

Make Sure The Work Area is Well Vented

When working with any wood materials, acrylics, or plastics laser engraving will tend to emit fumes as well as very tiny particles. Without good ventilation, it can be harmful to your health. Make sure to use good exhaust fans paired with an air filtration system or alternatively, do your work in a space that is well ventilated. If neither of those is possible, be sure to use supplementary equipment that can effectively get rid of any smoke or particles in the air.

Monitor The Machine At All Times During Use

Due to the fact that lasers engraving machines operate at very high temperatures, there is a risk that a fire can start if the machine is not attended to. It can not be stated enough just how important it is to always monitor the machine to ensure anything flammable is handled with utmost caution. When you need to step away from the machine, be sure to press pause, turn off the machine, or step away.