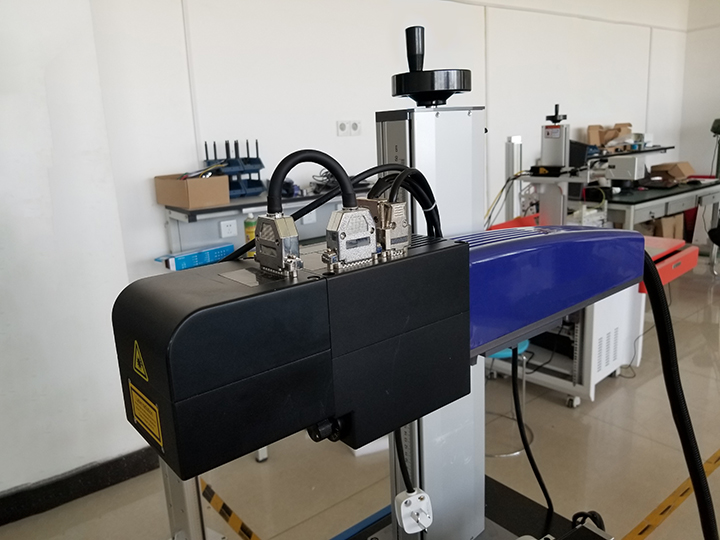

3D fiber laser marking machine is a 5-axis laser texturing system used to etch on 3D curved metal surfaces and deep engraving textures & reliefs on metal molds, allowing for the creation of three-dimensional designs on various metal materials at variable depths using a high-intensity laser beam.

3D fiber laser marking machine is among the 5-axis laser engraving machines that utilize a sophisticated front focusing method to control and operate the dynamic focus lens through 3D marking software and perform variable beam expansion before the laser is focused, thereby changing the focal length of the laser beam. Get precise engraving of text, symbols, and patterns onto the 3D surface. It is also termed as a 3D laser engraving machine, 3D laser texturing machine, 5-axis laser engraving machine, and 5-axis laser marking machine.

3D fiber laser marking system can mark various 3D marking modes such as inclined surface, step difference, cylinder, cone, spherical surface, and curved surface that cannot be marked by the traditional marking machines before. The 3D laser texturing machine has a long service life, easy maintenance, and high-speed marking, which greatly enhances working efficiency.

When it comes to precision engraving, 3D fiber lasers have revolutionized the industry. Unlike traditional laser engravers, they offer greater depth, accuracy, and versatility on various materials. If you need high-quality markings with complex details, here are the key reasons why a 3D fiber laser is the better choice.

Engraves 3D Complex Surfaces with Ease

A 3D fiber laser engraves complex, irregular, and multi-layered surfaces easily. Unlike traditional engravers that cannot cope with depth variations, 3D fiber lasers focus dynamically and therefore engrave uniformly on intricate items like jewelry, molds, and industrial parts.

More Precision and Detail

Basic laser engravers are appropriate for simple engravings, yet 3D fiber lasers are more accurate. They offer extremely fine details, which are perfectly suitable for detailed patterns, logos, and high-resolution markings on plastics, ceramics, and metals.

More Depth Control

With their variable focal lengths, 3D fiber lasers can engrave more deeply without distortion. Traditional type engravers become confused by variations in depth and create inconsistent work. For etching deeply, embossing, and engraving hard surfaces, 3D fiber lasers are ideal.

Works on a Wider Range of Materials

Whereas the standard laser engravers are used mainly for wood, acrylic, and coated metals, 3D fiber lasers are capable of cutting stainless steel, titanium, aluminum, and precious metals. With ease, they introduce precise, durable marks to almost any surface.

More Powerful and Faster Operation

Speed is important in manufacturing, and 3D fiber lasers provide high-speed engraving with little material loss. Their efficiency saves time and money in production, making them a superior option for companies that need mass production or high-detail engraving.

Long Lifespan with Low Maintenance

3D fiber lasers are more durable than traditional CO2 or diode lasers. With their robust fiber source and non-repeated part replacement requirements, they require very little maintenance and perform years of consistent, high-quality engraving.

1. High precision of 3D positioning technology, high-speed dynamic focusing and scanning system, short pulse, high-peak-power, and HPRF (High Pulse Repetition Frequency).

2. User-friendly operating interface is suitable for many file formats, such as dxf, plt, CNC, step, iges, and more.

3. High-strength cast machine structure makes the 3D fiber laser marking machine more stable.

4. IPG, Raycus, and JPT fiber laser generator for optional, the lifetime can reach 100,000 hours, 8-10 years without any consumables and maintenance. We have 2 years of warranty for the laser source, the diode coupling with fiber to process pump, the pump light will course the particles reverse which can emit a high-quality laser beam. This is the best choice for customers who have special requirements for the finest laser beam and features.

5. The high-tech product is a combination of laser devices, computers, auto controllers, and precision machinery.

6. Top brand scanning system makes the scanning speed up to 8000mm/s.

7. Afford the specific marking software based on Windows, which adjusts the laser power and pulse frequency. You can input and output by computer according to edit in both the specific marking software and the graphic software such as AutoCAD, CorelDRAW, or Photoshop.

8. Using laser software to control the optical expanded beam lens in the optical axis with direction high speed reciprocating motion, dynamic adjustment of the focal length of the laser beam, making focal spots in different locations to realize the 3D engraving.

| Model | STJ-100F-3D |

| Laser Source | Fiber Laser Generator |

| Laser Wavelength | 1064nm |

| Laser Power | 100W |

| Laser Beam Quality M2 | <1.8 |

| Pulse Repeatable Frequency | 1kHz~4000kHz |

| Cooling Method | Air Cooling |

| Marking Area | 100mm×100mm×30mm, 200mm×200mm×80mm |

| Max Speed in X-Y Axis | 600@100×100 Charaters/s |

| Focal Length | 114mm |

| Scan Angle | 11 |

| Repeatablity | 8urad |

| Operating Ambient Temperature | 18~28℃ |

| Power Demand | 220V/50HZ, 110V/60HZ |

| Overall Power Consumption | 0.8KW |

The advancement in laser technology produced 3D fiber laser marking as a superior system than traditional 2D laser engraving. The 2 methods create permanent marks but they operate with different functionality mechanisms and depth adjustment options as well as differing material applicability. Each engraving distinction serves as a guide to enable businesses in picking their preferred marking solution.

| 3D Fiber Laser Marking | 2D Laser Engraving |

| Engraves on curved, sloped, and irregular surfaces with depth control. | Works only on flat or slightly curved surfaces. |

| Offers precise multi-level engraving with variable depth. | Limited to shallow engravings with fixed depth. |

| Suitable for metals, plastics, ceramics, and coated materials. | Primarily used for wood, acrylic, and coated metals. |

| High-precision, fine-detailed markings with consistent quality. | Produces quality engravings but lacks depth flexibility. |

| Faster marking process with high efficiency. | Slightly slower process due to depth limitations. |

| Long lifespan with minimal maintenance required. | May need frequent adjustments and part replacements. |

The superior selection for technical marking needs involving complex surfaces with precise deep engravings goes to 3D fiber laser marking yet 2D laser engraving remains appropriate for basic flat-surface needs. The ability to understand engraving differences makes businesses better able to obtain maximum efficiency alongside improved quality in their engraving processes.

This 3D fiber laser marking system provides appropriate marking solutions for different metal and nonmetal materials with their 3-dimensional curved surfaces. The system finds applications throughout the mobile manufacturing sector and the production of cubic circuits and medical equipment while serving molds and 3C electronics and auto parts and electronic communication.

The 3D fiber laser marking system operates on mobile phone keypads, plastic translucent keys, electronics components, integrated circuits (IC) and electrical appliances, communications products, sanitary ware, tools, accessories, guns, firearms, credit cards, knives, eyeglasses and clocks, jewelry, auto parts, luggage buckle, cooking utensils, stainless steel products, and other industries.

Electronic Components: Electronics consist of resistors, capacitors, computer chips, printed circuit boards together with computer keyboards.

Apparatus & Meter: The experiment utilized panel signs and precision equipment as apparatus and meter.

Instrument: The instrument requires marking of small objects using panel signs accompanied by nameplates.

Hardware Tools: The set of hardware tools includes knives combined with tools and measuring tools and cutting tools.

Automobile Parts: Automobile parts consist of pistons along with piston rings, gears, shafts, bearings, clutch and lights.

Mechanical Parts: The collection comprises bearings along with gears and regular components along with motors.

Daily Necessities: Handicrafts, zipper, key holder, sanitary ware.

Jewelry: Rings jewelry, gold, silver.

Food & Drinking Packing: Plastic packings, metal packings.

Metals (including rare metals), engineering plastics, electroplating materials, coating material, plastic, rubber, epoxy resin, ceramic, plastic, ABS, PVC, PES, stainless steel, copper, aluminum, gold, silver, and other materials.

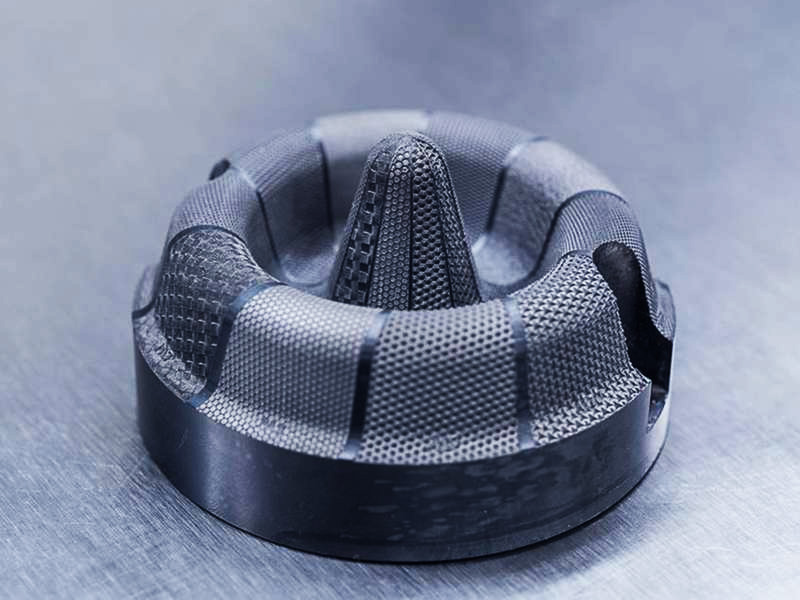

3D Laser Texturing Projects

3D Laser Engraved Metal Projects

3D Laser Engraved Cookware Projects

Fiber Laser Engraved 3D Surface

Fiber Laser Engraved 3D Projects

3D Relief Engraving Metal Projects

3D Laser Deep Engraving & Cutting Projects

To generate deep and durable textures from a 3D fiber laser system users must master power control and speed management together with layering strategies. Checks in platform settings result in superior quality outcomes for all industrial, branding and artistic engraving purposes. Businesses can produce extensive texturing that lasts long-term by following these essential steps when operating a 3D fiber laser.

Adjust Power and Frequency

The depth of engraving increases when you use more powerful laser systems which can accompany maximum material removal through frequency control. Perfect setup conditions will protect the engraving from overheating while minimizing distortions and keeping the finished product clean. Different sets of parameters based on materials require a trial-and-error process to deliver optimal results without weakening the material structures.

Use Multiple Passes

Proceeding with a single pass might result in insufficient texturing for advanced engraving work. Material degradation happens in precise segments through staged passage operations. Changing the focal position on multiple passes generates flat surfaces and adds depth to create crisp texture patterns that avoid burned areas and avoid markings from being uneven.

Optimize Focus

The achievement of both deep engraving depths together with sharp edges depends directly on proper focus settings. With its feature of adjustable focus a 3D fiber laser can handle irregular and contour-shaped surfaces during engraving operations properly. Adjusting focus by a small amount makes the engravable zone depth equal for consistent uniform marking.

Control Scan Speed

Lowering the system speed unlocks increased laser power that penetrates deeply into the material. Slowing down operations to their lowest limit will produce excessive heat buildup. A proper mixture between power parameters and scanning speed controls the removal process to create a durable high-contrast textured surface.

Apply Texturing Patterns

The implementation of cross-hatching and waveform texturing patterns through software leads to both elevated durability and permanent results. Software-based surface patterns improve beauty and visibility while industrial stamping uses them for metal marking and anti-counterfeiting processes. This technology also creates ornamentation marks on plastic and metal materials and ceramic surfaces.

Provide Adequate Cooling and Post-Processing

Minimal thermal damage occurs when an effective cooling system is used and engraving consistency remains maximal. The final stage of texturing requires air together with weak solvent methods to clean debris and make the components more durable. The application of protective coatings with oxidation treatments leads to preservation of the texture in a form that withstands both wear and environmental elements.

A suitable 3D fiber laser marking machine brings both precision capabilities as well as enhanced efficiency and reliable operation. Different machine models exist in the market which means finding the best one requires analysis of 3 core elements that include application requirements combined with material compatibility and system performance capabilities. Several important factors will lead you toward choosing the best 3D fiber laser marking machine.

1. Determine Your Engraving Needs

The 1st requirement in picking an appropriate machine demands understanding the application requirements. Your choice between deep engraving or surface marking or high-speed production depends on selecting from a variety of models with different power capabilities and beam quality features. Your targeted application requires a machine that matches all your needs through specific use case identification.

2. Check Power and Frequency Options

The machine's laser power rating together with its operational frequency sets the depth range and working speed during engraving operations. A machine that operates at 50W to 100W power is best for creating deep engraving results while equipment running at 20W to 30W power level produces the most detailed markings. You can set adjustable frequencies to improve performance with various materials which enhances both operational output and product quality.

3. Evaluate Material Compatibility

A wide range of materials does not have suitable operations with 3D fiber lasers. Make sure to select a machine which properly engraves your working materials including metals and plastics along with coated materials. Multi-material competency differs from model to model which allows applications across both manufacturing and art production needs.

4. Look for Advanced Autofocus and Software Features

The combination of intelligent software with an autofocus function makes 3D fiber lasers more effective for precise engraving depth control. Production consistency improves on irregular surfaces because the technology provides real-time preview functions and adjustable Z-axis controls along with automatic focus correction methods. The system makes operations simpler and increases efficiency.

5. Consider Work Area Size and Machine Dimensions

The area size of the marking function sets the maximum size limitation for an engraved workpiece. A machine that provides a big marking area should be your choice if you need to engrave big items. The engraving capacity of compact models fits small objects well yet restricts possibilities in creating bigger dimensional engravings.

6. Compare Cooling and Maintenance Requirements

Efficient cooling systems prevent overheating and prolong the machine’s lifespan. Air-cooled systems require less maintenance, while water-cooled options offer better performance for heavy-duty use. Understanding maintenance needs helps ensure long-term reliability and minimal downtime.

7. Check Warranty and Support Services

Investing in a 3D fiber laser is a long-term decision. Choose a machine with a solid warranty, reliable technical support, and access to replacement parts. A reputable brand with good customer service ensures a hassle-free experience and ongoing assistance when needed.

What's the package of the 3D laser engraving machine?

We have a 3-layer package. For the outside, we adopt a wood craft case. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by a thickening plastic bag for waterproofing.

Will the package damaged during transportation?

Our package considers all the damage factors and makes it safe, and our shipping agent has full experience in safe transportation. We have exported to 180 countries worldwide. So please don’t worry, you will receive the parcel in good condition.

How to install and run the 3D laser etching machine?

Our technician installed the machine before shipping. For some small parts installation, we will send a detailed training video, and user’s manual along with the machine. 95% of customers can learn by themselves.

What can I do if the 3D laser texturing machine goes wrong?

If confronted with such problems, please contact us ASAP and do not try to fix the laser marking machine by yourself or someone else. We will respond within 24 hours as quickly as we can to solve it for you.

The best 3d laser supplier to work with. High-quality F-theta lens is much better than the lens I bought from other companies. This will help to get the most out of the engraver.