Yes, we offer paid/free ArtCAM, Type3, Mach3, Cabinet Vision, Alphacam, UcanCAM, LaserCut, CypCut, CypOne, RDWorks, EZCAD, Laser GRBL, Inkscape, EzGraver, SolveSpace, LaserWeb, LightBurn, Archicad, and more software with CNC machines purchased from STYLECNC, so it will be more convenient for you to operate the machine.

We helped a lot of beginners in CNC machines, if you have a basic knowledge of computers and are willing to spend a little time on learning, it is not too hard. When you ordered a CNC machine from STYLECNC, we will send the user manual and operating videos to you, you can also get the 24/7 free online service by calling, email, whatsapp, livechat or remote desktop with teamviewer.

STYLECNC provides free consultation, business solutions, quotations, and sales services for machines and accessories for sale, and provides technical support for transportation, distribution, installation, commissioning, operation, and repair of sold machines, and provides lifetime installation , debugging and maintenance services for software.

Pre-Sales Service

1. Free Sample Cutting Service: For free sample cutting/testing, please send us your CAD file (PLT, AI), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Progressing Solution Design: According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

3. Customized Machine Design: According to customer's application, we may revise our CNC machine according to customer's convenience and high production efficiency.

After-Sales Service and Technical Support

1. As a professional CNC machine manufacturer and supplier, STYLECNC will supply the CNC machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote, such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problems of installation, operation or adjusting.

2. You can come to our CNC machine factory for training. We will offer professional guidance, direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3~5 days.

3. Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses and accommodation to us during the business trip and service period before their dispatch.

The cost of your shipment will depend on its origin, destination, value of CNC machines shipped, service, package weight, size, delivery times, and some unexpected considerations. To get the shipping cost of your CNC machine from STYLECNC, feel free to tell us.

You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we'll estimate the final price for your CNC machine.

Please note, customs fees and additional fees may apply for international shipments. Contact your local customs office for more information.

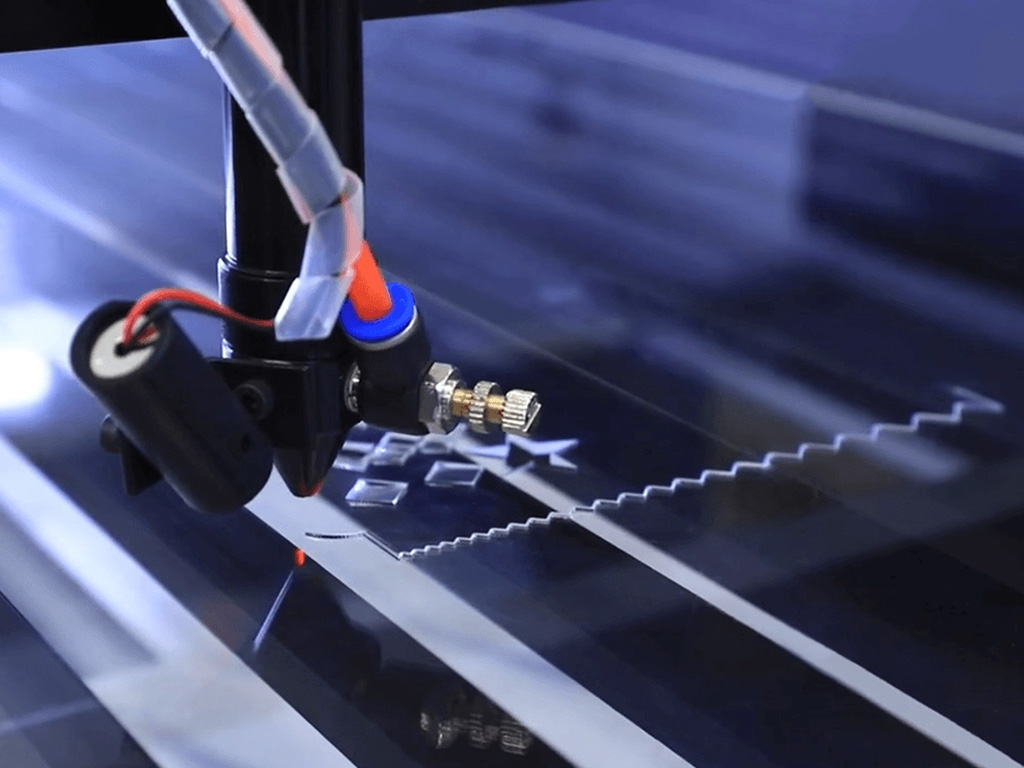

Laser-cutting acrylic is a of the latest additions to our technological advancement that enables an efficient fabrication process of acrylic sheets and offers unparalleled precision in engraving, carving, or shaping them. This high-powered tech opened a world of creative possibilities.

But, today we are not going to praise the laser cutting of acrylic with what it can do. Rather, in this post we will be exploring the safety considerations of this tech and find out if it is toxic or not. We will also deliver safety measures and guidelines to follow before taking your project to the field.

The importance of understanding the safety considerations and following them is crucial. Let’s find out whether and how effectively the laser cutting acrylic revolutionized manufacturing industries.

Laser cutting acrylic uses high voltage concentrated laser beam to cut through the materials. It offers a wide range of applications. The laser beam precisely cuts through or engraves acrylic sheets. This is way better than traditional milling or sawing methods. Efficient productivity and ease of usability make laser-cutting acrylic sheets popular these days.

Utilizing the intense heat generated by the laser cuts and shapes the material with smooth finishing and clean edges. Laser cutter offers superior accuracy to the task.

This newly added tech is undoubtedly more beneficial than any traditional milling and cutting methods. However, laser cutting acrylic also leads to potential hazards and safety risks. Today, our primary concern is the safety considerations and importance of those laser cutting acrylics.

Safety considerations in laser cutting acrylic are crucial. Lack of safety measurement will cause several hazards, such as health hazards, inhalation difficulties, eye injuries, skin irritation sensitization, and so on.

To avoid any unwanted experience follow these rules and make sure safety features are enabled.

✔ Proper ventilation is very important at work. The process creates fumes and gasses. Direct inhalation exposure can cause severe health issues within days.

✔ A complete PPE set can save you from many long-term physical diseases due to working with the laser beam. A proper PPE setup features organic vapor cartridges and safety goggles to protect against inhalation of fumes and potential eye damage from laser radiation.

✔ Make sure regular maintenance to maximize efficiency and performance. This will also save you from any potential machine malfunction or accidents.

✔ Emphasize the training and education of the operators. With proper knowledge and expertise, an operator can save the machinery along with him from any potential disabilities.

✔ Practice and ensure regulatory compliance provided by legal authorities.

Now, safety considerations bear great importance and significance due to probable hazardous incidents. Therefore, STYLECNC recommends prioritizing the safety steps to attain physical and financial safety on top.

Laser cutting uses high-voltage electric power to generate high-temperature heat. The concentrated laser beam then vaporizes the material with a predetermined path by a CNC software system and shapes the item accordingly.

In this whole machining process, a few chemicals and bi-products are produced as waste. Here, we have given a brief look at the chemicals produced during laser cutting acrylic.

The properties of Methyl Methacrylate and the health effects due to this chemical exposure are given below.

• Methyl methacrylate is a colorless liquid with a sweet odor

• Commonly used in acrylic plastics, adhesives, coatings, and resins production

• Skin contact can cause irritation, redness, and dermatitis for skin-sensitive personnel

• Even a short-time exposure to concentrated MMA can cause respiratory tract

• MMA is also considered a potential carcinogen

Now the exposure limits and regulations in laser cutting acrylic are necessary to learn and follow.

OSHA and ACGIH established exposure limits and guidelines for MMA to protect workers from diverse health effects. The OSHA permissible exposure limit (PEL) for MMA is 100 parts per million (ppm). The ACGIH threshold limit value (TLV) for MMA is 50 ppm as an 8-hour TWA.

Knowing the health hazards and carcinogenicity of Formaldehyde will certainly help keep you on a safe track. It is a colorless gas with a distinct odor. Health hazards prone to take cause are likely,

• Inhalation of the gas can irritate the eyes. Besides, the nose, throat, and respiratory tract are common hazards of the exposure

• Repeated and long exposure to Formaldehyde is responsible for severe health diseases like asthma, and bronchitis, as well as allergic reaction

• The International Agency for Research on Cancer (IARC) and the National Toxicology Program (NTP) classified Formaldehyde as a known human carcinogen

To reduce hazards due to this chemical substance regulatory guidelines are established by OSHA and ACGIH.

The OSHA permissible exposure limit (PEL) for Formaldehyde is 0.75 parts per million (ppm) and the ACGIH threshold limit value (TLV) for Formaldehyde is 0.3 ppm as an 8-hour TWA. OSHA has established a short-term exposure limit (STEL) of 2 ppm as well for formaldehyde. This is crucial to know about the regulatory guidelines for all operators.

This is a highly toxic element found during the production of materials with coating and additives. Specific coated acrylic products can produce HCN. During acrylic cutting high temperature of the laser can produce a decomposition product like cyanide.

The health risks of this chemical element are high. So, safety measures for acrylic laser cutting are a must.

Inhalation of hydrogen cyanide vapor can lead to symptoms such as headache, dizziness, nausea, vomiting, difficulty breathing, and in severe cases, loss of consciousness and death. To minimize the chances of any health issues ensure the following steps,

Proper ventilation system, and personal protective equipment (PPE), monitor performance, and train the workers with adequate knowledge.

Neglecting the importance of safety considerations and not following them can cause severe physical harm. Working for a long time to exposure to HCN can cause death.

Respiratory effects

• Irritation and discomfort: Exposure to fumes and gas and inhalation of irritant substances such as Methyl Methacrylate and formaldehyde, can cause acute respiratory irritation.

• Long-term health implications: Chronic exposure to acrylic fumes causes respiratory diseases such as bronchitis, asthma, and chronic obstructive pulmonary disease (COPD).

Skin and Eye Irritation

• Contact dermatitis: Contact with acrylic fumes can lead to contact dermatitis. Symptoms of contact dermatitis may include redness, itching, swelling, and blistering of the skin.

• Eye irritation and damage: Exposure to laser radiation consistently can cause eye irritation and damage.

Safety precautions are essential to reduce the chance of accidents while laser cutting acrylics. Follow the safety measures and ensure a safe work environment. Some important safety measures are,

✔ Make sure proper ventilation in the cutting area to remove fumes and gases.

✔ Install fume extraction equipment or local exhaust ventilation.

✔ Provide appropriate PPE to the operators and workers.

✔ Make sure the workers wear respirators with organic vapor cartridges to avoid direct inhalation of fumes and gases.

✔ Use safety goggles and protective gloves on working.

✔ Ensure routine inspection and maintenance check-ups of the laser acrylic cutting machine.

✔ Train operators and workers.

✔ Follow the instruction manual given by the manufacturer.

Relevant regulations and guidelines for regulatory compliance are made to ensure the safety of the health and workers of cutting acrylic. These standards are established and approved by the Occupational Safety and Health Administration (OSHA), the National Institute for Occupational Safety and Health (NIOSH), and the International Organization for Standardization (ISO).

The OSHA regulations are:

⇲ Hazard Communication Standard (HCS).

⇲ Respiratory Protection Standard.

⇲ Personal Protective Equipment (PPE).

⇲ Ventilation Standard.

NIOSH also features a couple of standard guidelines for workers engaged with laser cutting acrylic for exposure to both Methyl Methacrylate and Formaldehyde.

There are a few ISO standards as well to follow.

To ensure a safer laser cutting operation operators and owners must follow all the safety considerations and regulations we talked about. A few tactics to make sure workers are healthy and safe are given below.

Training and education for operators

Provide comprehensive training to your workers for laser cutting acrylic including setup, shut down, and operation. Make sure they are trained for emergency response.

Regular maintenance of equipment

Take routine inspections of machines and parameters. Check parts and components like laser sources, optics, cooling systems, and safety interlocks, to identify and address any signs of wear, damage, or malfunction.

Monitoring and testing for air quality

Do take regular ventilation checks and install essential equipment to make sure the environment and air quality are breathable.

STYLECNC values your business and always attempts to provide you the best service and support.

No limited warranty is provided by STYLECNC unless your CNC machine was purchased from STYLECNC or an authorized distributor as well as an authorized reseller. Please see below for the warranty information.

As a top CNC machine brand & manufacturer in the world, STYLECNC promise:

1. 1-3 years for the whole CNC machine.

2. Long life-time maintenance, after-sale department will offer 24/7 English online support.

3. Except the damage artificially, we are responsible for offering the fittings free of charge during warranty.

4. After the warranty period expired, you only need to pay the actual maintenance cost.

5. Certificate support: CE, FDA, SGS.

1. Focus lens for contamination: Clean focusing mirror.

2. Focus relief laser engraving machine equipment whether changes: Re-adjust the focus.

3. Light path is offset: Carefully adjustment of the optical path.

4. Reflective lens is contaminated or damaged: Clean or replace the reflective lenses.

5. Laser power is energized: Checking laser power supply circuit so that it is normal.

6. Laser tube is damaged or aging: Replace the laser tube.

7. Laser power supply is damaged: Replace the laser power.

8. Cooling water is circulating flow: Clear cool water.

9. The cooling water temperature is normal or not: Replace the clean cooling water to the temperature to normal.

What I tell you about the laser weaker of laser engraving machine? we have to know how the above problems to be fixed, and welcome to our online support with laser engraving machine.

Laser cutting technology has advanced the cutting methods and precision ever more than before. The cutting is done using a concentrated laser beam at high temperature. This technology is welcomed in almost every industry. The versatility of the machines makes laser cutting more popular and outstanding.

It features the usability of a wide range of materials to shape, carve, or engrave. But in particular, plastics require more attention while making a project with them. Yes, Laser cutting polycarbonate is possible. You just need to know how to find the best suit for your project and fix the machine properly with accurate parameters.

Today, we are going to discuss the versatility of laser cutting technology and how to use it most efficiently. We are also going to break down the fact if laser cutting polycarbonate is possible or not, and if possible how to do that. Let's dive into the mastery of manufacturing cutting tools.

Unlike traditional cutting and sawing methods laser cutting introduces a high-temperature laser beam-cutting tool that offers the most precise and efficient manufacturing outcome. The laser is usually focused and controlled through CNC router machines.

There are 2 common types of lasers used for the job.

1. Carbon Dioxide (CO2) lasers and

2. Neodymium-doped yttrium aluminum garnet (Nd:YAG) lasers.

The CO2 laser is suitable for non-metals like wood, acrylic, and fabric. On the other hand, Nd: YAG lasers are used for cutting metals and are capable of higher power outputs.

Laser cutting is used on a wide range of materials (metals and non-metals). Currently, laser cutting is available for cutting, engraving, or shaping steel, aluminum, copper, wood, acrylic, plastic, leather, fabric, rubber, etc.

Laser cutting polycarbonate can be done with caution since many plastics are not suitable to cut using heat. It is important to know what kind of plastic you are going to cut.

The thickness and material density also impact the cutting. All plastics are not recommended to be cut using a laser. Specifically talking about polycarbonate, they cut very poorly and often discolor and catch fire. Usually, this material is found as sheets. For some specific reason laser cutting polycarbonate is not recommended for all purposes.

Therefore, due to the lesser effectiveness of laser on polycarbonate, it is considered a poor choice to use laser cut. But if necessary and with better thickness laser cutting polycarbonate is possible. Let’s see what are the potential difficulties to face while laser cutting polycarbonate.

Polycarbonate tends not to work out with the laser cutting method. Yet you can get your job done only by following precautions and proper steps. But first, let’s find out the various challenges to face while laser cutting.

✔ Generation of hazardous fume: High high-powered laser beam can generate toxic gases like carbon monoxide and hydrogen cyanide. In the absence of proper ventilation, this can cause severe health conditions.

✔ Material sensitivity to heat: Polycarbonate is sensitive to heat. Extra heat can cause this material to melt, burn, or undesirable surface.

✔ Potential for thermal stress and warping: Thermal stress is common with overheating laser beams. This often leads to discoloration and distortion of material. It also affects dimensional accuracy and fit of the final product.

✔ Difficulty achieving clean edges: Achieving clean and smooth edges is challenging while laser cutting polycarbonate. Initially, the edges are prone to melt and tend to regain their shape. Meanwhile, the edge loses smoothness and shape.

✔ Effects of additives and coatings: Polycarbonate sheets with additives and coatings come with more challenges. When the material is heated these additives and coatings produce additional toxic gases and bi-products.

Besides, the risk of surface damage, the complexity of parameters optimization, and regulatory compliance and safety standards are a few factors that face additional challenges.

Unlike laser cutting, there are more effective cutting methods for polycarbonate. The best way to cut polycarbonate depends on several factors such as thickness, desired precision, etc. We have gathered a few ways considered most effective in cutting polycarbonate. Let’s find out which works best for you.

B. CNC Router

C. Table Saw

D. Jigsaw

E. Score and Snap Method and

F. Waterjet Cutting

They are proven useful with fewer challenges and better precision to a certain extent.

Plastic materials are not eco-friendly materials for our environment. Yet versatile composition makes them useful in many industries. Cutting polycarbonate using laser cutting technology requires special safety precautions.

The safety precautions need to be improvised actively. Here are a few key safety considerations,

✔ Proper ventilation is a must to remove toxic gases and contaminants. Use an exhaust system to remove fumes effectively.

✔ Use the suitable equipment only to maximize the smoothness and accuracy of the shape.

✔ Try to use polycarbonate sheets specifically made to laser cut. Take necessary steps if additives or coatings are available on the sheet.

✔ Wear an appropriate PPE set at work. Make sure your PPE comes with gloves, masks, and protective clothing.

✔ Fire safety is very important in laser-cutting polycarbonate. Keep a fire extinguisher nearby. Keep the flammable objects at a distance.

✔ Dispose of plastic waste properly.

Cutting polycarbonate can be difficult in certain work environments. However, a few tips can come in handy. Try them out to get better results.

1. Select the right tools

Choose the appropriate cutting tools based on the thickness of the sheet. Use a table saw on thin sheets and jigsaw for curved or irregular cuts.

2. Use proper cutting techniques

Fix the sheet properly on the bed to avoid chipping or cracking. When using table saw use clamps to secure the sheet. Using a jigsaw? Move it slowly and steadily.

3. Optimize cutting parameters

Considering thickness adjust the cutting speed, feed rate, and blade speed. Try different settings to find the optimal balance.

4. Minimize heat buildup

Avoid excessive friction using sharp-edge tools. This will reduce the overheating issue. Apply cutting lubricants or cooling agents for more effective results.

5. Protective measures

Wear proper PPE set and use a dust mask.

6. Clean up

Remove debris and wastage immediately. Use sandpaper to bring smooth and clean edges.

Laser-cutting polycarbonate usually results in discoloring. Not following the proper usage instructions results in this discoloration problem!

Now, what are you going to do once the product comes with discoloration? We have given you a few ideas that may improve the final result. You can follow them step by step to get rid of this unwanted condition.

⇲ Allow the material to cool

⇲ Gently remove surface debris

⇲ Prepare a cleaning solution

⇲ Apply the cleaning solution

⇲ Rinse thoroughly

⇲ Buff with polishing compound

⇲ Check and repeat if necessary

You can apply a protectant additionally to prevent future discoloration.

Fiber laser cutting is more popular among consumers for cutting polycarbonate. A suitable polycarbonate sheet can ensure an efficient cutting result. A proper parameter setup is also responsible to avoid overheating and prepare a smooth cutting action.

Follow the thermal precautions given at the top of the article and you are all good to go.

Post-processing is also a significant task to finally achieve a proper production. Follow the safety considerations available for laser cutting polycarbonate.

Polycarbonate and acrylic are 2 different materials. In terms of applying similar cutting methods, both can result in contrasting. Let’s take a look at the similarities and dissimilarities of laser cutting polycarbonate and acrylic.

| Laser Cutting Polycarbonate | Laser Cutting Acrylic |

|---|---|

| Polycarbonate is a thermoplastic polymer known for its strength, durability, and impact resistance. It is transparent and commonly used as a substitute for glass due to its lightw8 and shatterproof properties. | Acrylic, also known as PMMA (polymethyl methacrylate) or Plexiglas, is a transparent thermoplastic that resembles glass but is lighter and more impact-resistant. It is often used as a cheaper alternative to glass in various applications. |

| Polycarbonate absorbs fiber laser wavelengths, making it suitable for cutting with fiber lasers. However, care must be taken to avoid excessive heat buildup and potential thermal damage to the material. | Acrylic is transparent to CO2 laser wavelengths, making it well-suited for cutting with CO2 lasers. CO2 lasers are commonly used for cutting acrylic due to their ability to produce clean, precise cuts with minimal heat-affected zones. |

| When laser cutting polycarbonate, it's essential to control heat buildup to prevent melting or charring of the material. Fiber lasers are typically used for cutting polycarbonate, and proper parameter optimization is crucial to achieve clean, precise cuts. | Acrylic cuts cleanly and efficiently with CO2 lasers, which are well-suited for cutting through the material without excessive heat buildup. CO2 lasers offer high precision and can produce intricate designs with smooth, polished edges. |

| Laser-cutting polycarbonate can sometimes result in rough or melted edges due to heat buildup during the cutting process. Proper parameter optimization and post-processing may be necessary to achieve smooth, clean edges. | CO2 lasers produce clean, polished edges when cutting acrylic, resulting in high-quality finished products with minimal post-processing required. Acrylic is well-suited for applications where optical clarity and edge quality are critical. |

| Polycarbonate is commonly used in applications requiring impact resistance and durability, such as safety shields, protective covers, and machine guards. Laser-cutting polycarbonate is suitable for creating custom shapes and designs in these applications. | Acrylic is widely used in signage, displays, lighting fixtures, and architectural applications due to its clarity, versatility, and ease of fabrication. Laser-cutting acrylic allows for precise cutting of intricate designs and letters for these applications. |

1. When laser engraving with gradient, double phenomenon.

This phenomenon occurs when the slope of words carved smaller, usually the reason is "wide" setting slope too large, cause calculation errors, please set "wide" little slope.

2. If you only can move a graphic with one direction, please click "Shift" or "Ctrl" to recover.

3. PLT format cannot to engrave.

There are 2 reasons, one is the graphic is not closed, the other is graphic double. Please detect this phenomenon with "data detect" tools.

4. The size is not same with laser engraving and cutting samples. Open the item "laser engraving machine set", adjust the pulse.

5. The edge is irregularity when laser engraving.

The edge is irregularity maybe happen when you use the DSP laser engraver software, that means "burr", this is mainly caused by mechanical return clearance, this is the solution.

a. Draw a box (rectangular or square), set work mode for the laser engraving machine, the sculpture is 0.5 mm instead, then see laser engraving effect, theoretically, should be aligned, namely the odd interlaces did edge should be aligned, even did edge also should be aligned, only the odd and even did not have a little.

b. When you open "set laser engraving parameters", the parameters for different. laser engraving speed can be seen, the reverse gap is "0", you should adjust it as the matter of fact.

c. You can choose "single-track light" when best laser engraving effect needed. Not to chose the draw of "dual-engrave", but when you chose it, the efficiency would be lower.

6. The X-axis or the Y-axis not move.

a. Stir knob to chose the DC 5V, test the voltage between PULX(or PULY)and GND. Take Y axis as example, click the button of "up" or "down", the normal voltage is 2.8V, if it is not, we could confirm the controller was broken, please change the controller. If it is, please go to next step.

b. Exchange the output terminal of the 2 drivers, then press "Up" or "Down" button; if X axis works normal, it means there is something wrong with the motor on Y axis, please change a new one; if X axis doesn't work, it means there is something wrong with the driver on Y axis, please chance it.

7. X Axis and Y Axis work in only one direction.

a. Test the voltage between the DIRX and GND after pressed the multimeter into grade 5V; take the X Axis for example, press "left", then press "right" to see if there is some change on high level (>2.8V) and the low level(<0.8V); if not, the control card is broken and need to change a new one.

b. If with change, please check the driver; if works normal, please change the driver on Y Axis.

8. NO Ray.

Test the voltage between the LAS and GND after pressed the multimeter into grade 5V; press "fixed fire" in the control panel, to see if there is some change on high level (>2.8V) and the low level(<0.8V); if not, the control card is broken and need to change a new one. Also set up the time of fixed fir as 0 millisecond, which is in the PAD03 menu.

Adjust the power from 0%~100%, enter and press "fixed fire" button, then test if any change between the DA1 and GND from 0V to 5V; if not, the control card is broken, please change it; if both with, it means there is something wrong with the laser power supply.

1. The machine and the computer must have a good grounding.

2. Open the cutting software, click the file menu, communication settings to receive and send the buffer time is changed to 5 or 10.

3. The replacement of the data line or motherboard.

According to the same direction of the panel button, the laser cutting machine appears to be turning and reversing and motor power can not be locked.

1. First disconnect all power supply, the high pressure head with cotton cloth to wipe clean. (gentle scrub)

2. Cut off the broken pipe, re received the laser tube. And bundled with a tie.

3. The high voltage line (high pressure line with 7 silver thread, one less).

4. The fan will dry high pressure wet place, after half an hour, and then boot.

Note: If you can't find your answer in the FAQs above, please ask a new question in the form below.

Asking questions is essential in CNC machining for fostering understanding and encouraging exploration, allowing individuals to gain deeper insights and challenge assumptions, ultimately facilitating learning and innovation.