2025 best CO2 laser wood marking machine is used for engraving MDF, plywood, bamboo to DIY personalized wood crafts, gift box, wood arts, wood paint, wood frame, keyboard, mobile case, cover, and more woodworking projects.

CO2 laser wood marking machine is a laser galvanometer marking machine that uses computers, a CO2 laser generator, and a laser marking control card to engrave text, patterns, images, numbers, lines, names, dates, logos, signage on hardwood, softwood, MDF, plywood, and bamboo. The CO2 laser is irradiated on the surface of the wood. The surface of the wood absorbs the laser energy and generates a thermal excitation process in the irradiated area, which causes the surface temperature of the wood to rise, causing metamorphosis, melting, ablation, and evaporation.

• Adopting CO2 laser tube as the laser source. By 2D high-speed scanning mirrors swinging at the scheduled angles under the control of the computer, the laser focuses on the surface of the workpiece by F-θ lens to form images and realize marking and graph processing.

• Adopting top brand optics lens, low loss, excellent focalization performance.

• Using high-speed scanning mirrors, can be the graph in the shortest time finish fine marking process.

• Adopting an American high-speed galvanometer system with high speed, high precision, and stable performance.

• The marking software is mightiness, under the WINDOWS interface, compatible with CORELDRAW, AUTOCAD, PHOTOSHOP, etc. a variety of software output files. Support PLT, AI, DXF, BMP, and other documents, directly using SHX, TTF font.

• Support automated coding, serial number, batch number, date, bar code, and 2D code marking.

Applied Industries

CO2 laser wood marker is used for electronic components, medicines, food, drinking packages, leather products, rag trade, woodworks, craftworks, and packaging.

Applicable Materials

CO2 laser wood marking system is suitable for nonmetal materials such as leather, cloth, wood, MDF, plywood, bamboo, paper, organic materials, plastic, epoxy resin, etc.

CO2 Laser Wood Marking Machine for Wood Mobile Case

CO2 Laser Marking Machine for Wood Crafts

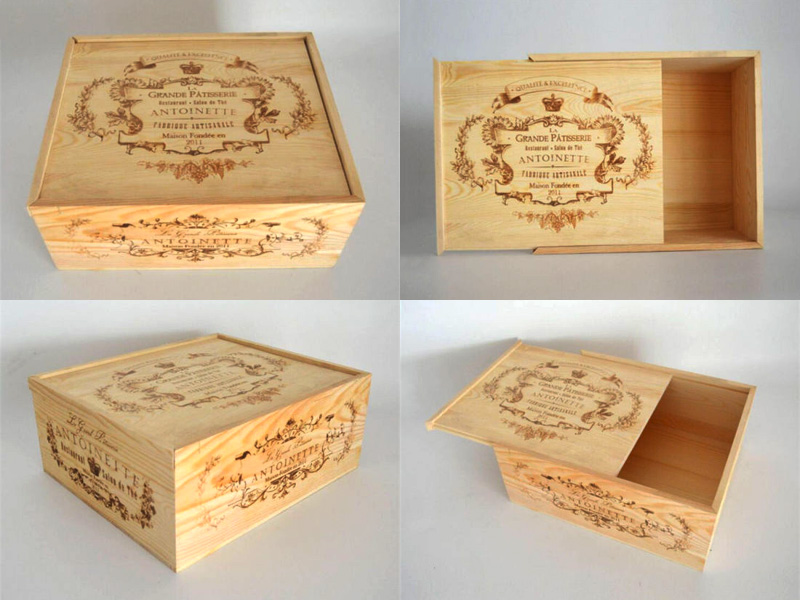

CO2 Laser Marking Machine for Wood Storage Boxes

| Model | STJ-80C |

| Maximum Laser Power | 80W |

| Laser Wavelength | 10.64μm |

| Laser Repetition Frequent | ≤25kHz |

| Standard Engraving Range | 100mm*100mm(200mm*200mm/300mm*300mm optional) |

| Marking Depth | ≤3mm |

| Marking Linear | ≤7,000mm/s |

| Minimum Linear Width | 0.1mm |

| Smallest Character | 0.4mm |

| Repeatability Precision | ±0.0025mm |

| Overall Power | 1.2KW |

| Power Required | 220V / single-phase / 50Hz / 8A |

| Control System | EZCAD |

| Cooing System Dimensions | Industrial CW5000 water chiller |

Beijing Reici 80w laser tube with exquisite beam quality, stable power output, high marking precision, long working lifetime, and can work for 20,000 hours free of maintenance.

We also have the America Synrad CO2 RF laser tubes for CO2 laser wood marking machines.

Professional industrial water chiller for cooling laser tubes.

2D working table, 3D table for optional.

American galvanometer system with high speed, high precision, and stable performance.

The process of laser engraving MDF and plywood requires proper settings in combination with specialized techniques for acquiring deep precise markings. The quality of results depends exclusively on factors which control laser power levels and operating speed together with airflow management. Follow the following 6 procedure points to achieve enhanced engraving outcomes.

Step 1: Choose the Appropriate Laser Power

Laser systems with considerable power of 50W and above prove most suitable for engraving deep into plywood and MDF. The decreased power setting will result in surface burning without creating depth and creating unbalanced effects. Begin with medium power setting while raising it progressively to achieve the desired depth while preventing material damage or charring.

Step 2: Set the Speed to Gain Better Depth

The time available for material burn increases when engraving rates remain low because of extended laser exposure. The laser needs sufficient processing time to penetrate deeply because quick operation modes prevent this from happening. The result of power regulation with speed control delivers strict outcomes for your project.

Step 3: Adjust the Focus for Sharpness

A properly focused laser beam produces precise and tidy engravings. For deeper engraving position the focal point at the material surface or beneath it by a small fraction of an inch depth. The correct choice of focus lens for your laser engraver increases accuracy during operation and prevents both harmful burns and unwanted blurred markings.

Step 4: Use Multiple Passes for Extra Depth

Multiple passes with lower power levels should replace using excessive power. The process enables gradually making marks into deeper areas of the material to avoid burn damage or material warping. The number of passes must adjust dependent on the thickness as well as density of MDF and plywood.

Step 5: Engage Air Assist to Prevent Charring

The air assist method removes smoke and debris thus protecting the material from burns and resulting in superior engraving quality. The absence of air assist can result in burnt surfaces along with unideal cut edges. Your laser engraving equipment needs a functioning air assist system for achieving precise marks with great engraving performance.

Step 6: Test and Fine-Tune Settings

Laser engraving produces different effects when applied to MDF and plywood materials because each material type responds individually to the laser process. Before starting your project work on rejected materials to evaluate settings. To achieve the best deep and precise marking results you need to modify power speed focus settings based on your testing outcomes.

A CO2 laser marking machine is a valuable investment, and proper maintenance ensures it operates efficiently for years. Regular cleaning, calibration, and part inspections help prevent breakdowns and costly repairs. Follow these essential maintenance practices to keep your machine running smoothly and delivering precise, high-quality results.

Clean Laser Lens on a Regular Basis

The dirt and dust outside the laser lens are at risk of reducing beam quality and affecting engraving accuracy. Clean the surface using the accepted lens cleaner and a soft lint-free cloth following a gentle touch approach. Your hand skin oil will ultimately destroy the lens when you attempt to touch it directly. Check and Position

Mirrors for Precision

Accuracy of marking can be compromised as laser beam mirrors slowly shift positions during long-term operation. Take the time to periodically adjust your machine mirrors through its screws to ensure alignment qualities. Positioning elements properly enhances the laser's working efficiency by decreasing the waste energy and enhancing elements engraved quality. Check the Exhaust System is Clear of Obstructions

Keep the Exhaust System Clear

CO2 laser operation produces smoke as well as fumes that condense into the working area and result in operational performance degradation. Make sure your electrical ventilation parts as well as exhaust fan function well under clean operation. Restricted air passage leads to workplace overheating as well as marking defects and potential safety risks.

Clean the Cooling System

The majority of CO2 laser marking machines make use of water or air for cooling to avoid overheating. Ensure coolant level checks and cleaning of water lines and coolant levels to avoid blockages. Replace water from a water chiller, if using one, every now and then in order to have the highest quality of cooling performance and guard internal parts.

Inspect and Tighten Belts and Rails

Loosely fitted or worn belts will cause uneven movement and create sub-quality marks. Check the motorized components, rails, and belts for wear regularly. Tighten or replace them as appropriate to maintain smooth functioning and even engraving output.

Do Regular Software Updates

Software updates of laser marking software usually include patches and performance optimization. Updated software guarantees compatibility with new features and brings overall efficiency to your machine. Updating regularly also prevents glitches that may interfere with your marking process.

In 2025, CO2 lasers continue to be the top choice for wood engraving due to their precision, speed, and versatility. Whether for business or hobby use, these lasers offer unmatched quality and efficiency. Here are 6 reasons why CO2 lasers stand out for engraving wood.

1. Higher Resolution and Accuracy

The accuracy of CO2 lasers enables them to make more precise detailed engravings compared to the standard methods. CO2 lasers can achieve neat engravings of texts and logos, as well as artworks, owing to the accuracy of CO2 lasers to place accurate marks free from charring and distortion.

2. High Speed of Engraving

CO2 laser production rates are significant in achieving high production levels because these machines offer high definition engravings at high speeds of operation. Companies' bulk production speeds quickly meet hobbyists' requirements for producing numerous projects fast with their high-speed machines. CO2 laser's high speed of operation reduces total production costs thus making them a cost-effective wood engraving method.

3. Works on Varying Types of Wood

A CO2 laser workstation effectively engraves plywood MDF hardwood softwood as well as veneer wood material. The system's power and speed settings enable the user to determine the best working parameters for various types of woods to avoid burning issues while executing engraving operations.

4. Repeatable and Accurate Results

CO2 lasers provide accurate output results in every engraving process without any human skill. The automated control system gives consistent results in every engraving which makes the system suitable for industrial production and branded merchandise production along with precise personalization of gifts.

5. Low Material Waste

The waste of materials in CO2 laser cutting is minimal because the process is clean cutting unlike traditional wood engraving tools that compromise material and generate excess waste. The accuracy of the laser beam offers precise cutting solutions that restrict unwanted burning devastation and chipping to enhance the utilization of materials which lowers business costs and independent creator expenses directly.

6. Low Maintenance and Long Lifespan

CO2 laser engravers possess long-lasting durability because their tubes function well while requiring minimal operator maintenance work. The maintenance of lenses alongside ventilator checks produces prolonged operational consistency across extensive periods. Proper maintenance makes CO2 laser engravers function as dependable wood-engraving tools that deliver precision and speed in their operations.

Great engraver, easy to start up, high precision and repeatability, but I would like to see some improvements in this machine, such as the table size, I think a larger working table will make this machine more widely used.