Looking for an affordable CO2 laser leather cutting machine to make personalized leather bags, leather bracelets, leather wallets, leather patches, leather purses, leather jacket, leather fabric, leather earrings, leather jewelry, leather shoes, leather tags, and more leather projects for commercial use? Here is the best 4x8 laser cutter of 2024 for synthetic leather, leatherette, and genuine leather.

A leather laser cutter is an advanced CNC laser-cutting machine used with the ability of a CO2 laser tube, which cuts, engraves, and etches leather materials accurately. Combining advanced laser technology with a superior motion control system, it has become a sizzling gadget in creating personalized leather products. From the type of leather to various projects, it is indeed required in various lines of industries, from fashion, upholstery, and custom accessory productions.

Leather laser cutters introduce accuracy and efficiency into leather working that is unparalleled. Be it a businessman, artisan, or designer, this tool makes complex designs quite simple to work with while delivering flawless results. The leather laser cutter is quite versatile; it can process many different types of leather, including:

• Synthetic Leather: Ideal for cost-effective designs with durable properties.

• Leatherette: A vegan-friendly alternative for eco-conscious projects.

• Genuine Leather: Popular for high-end products requiring authentic textures.

• Full Grain Leather & Top Grain Leather: Known for durability and luxurious finishes.

• Napped Leather & Suede: Preferred for soft, velvety textures.

• Embossed Grain Leather & Nubuck: Great for creating unique, textured designs.

• Bonded or Fiber Leather: A budget-friendly option made from leather scraps.

The wide compatibility with different leather types allows designers to experiment with textures, patterns, and styles, catering to diverse markets. A leather laser cutter is a versatile tool used in creating a variety of products, such as:

• Accessories: Leather bracelets, earrings, and tags.

• Fashion Items: Leather jackets, shoes, and purses.

• Home Décor: Upholstery, coasters, and fabric designs.

• Industrial Use: Saddlery, upholstery, and leather patches.

• Personalized Products: Wallets, jewelry, and tote bags.

From luxury goods to personalized gifts, a leather laser cutter adapts to numerous creative and industrial applications, boosting your production capabilities.

• On-Site Production: This machine supports real-time production, enabling quick project turnarounds.

• Precision and Speed: It delivers high-accuracy cuts with minimal waste, even on intricate designs.

• Efficiency: By doubling processing speeds and reducing manual effort, it significantly saves costs while increasing output.

• Interactive Design: The user-friendly interface allows offline operation and seamless integration into workflows.

Leather laser cutters are designed for efficiency, blending advanced technology with ease of use to optimize production processes.

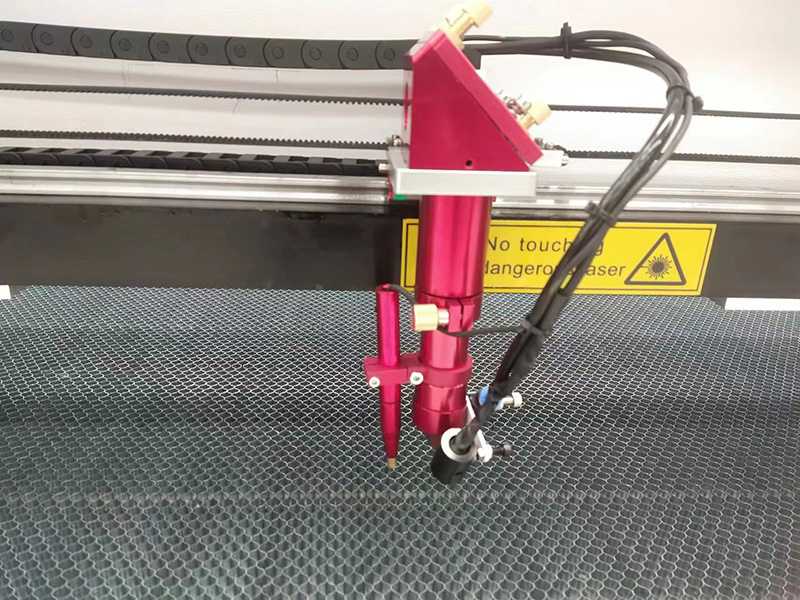

• Movement System: A motor and a belt or screw rod adjust the laser head’s position, ensuring precision cutting.

• Graphic Integration: Users can easily design custom graphics using software, enabling endless creative possibilities.

• Cutting Quality: The laser beam creates smooth, sealed edges that eliminate the need for post-processing.

Laser cutting technology has completely transformed leatherworking, allowing for precision, speed, and efficiency that traditional methods cannot match. The process involves focusing a high-powered laser beam onto the leather to achieve accuracy that is 2nd to none and at minimal material wastage. Next is a detailed breakdown of how leather laser cutting works and the many benefits it offers.

Understanding the mechanics of laser cutting reveals why it is a preferred tool for leather projects. Its advanced technology ensures precision while maintaining the integrity of the material.

The laser beam is concentrated into a tiny spot with an exceptionally high power density. This concentrated heat rapidly vaporizes the leather at the focal point, creating a precise and clean hole. As the laser moves along the material, these holes form narrow and consistent slits, ensuring an even cut. Minimal heat exposure to surrounding areas prevents warping, burning, or distorting the workpiece. The focused beam allows intricate patterns to be cut effortlessly, enabling detailed and custom designs.

• Purpose of Auxiliary Vapor: Enhances the cutting process by removing debris, improving cutting quality, and cooling the laser.

• Oxygen: Reacts with molten material, facilitating clean cuts and removing slag effectively.

• Compressed Air: Suitable for nonmetallic materials like plastics, minimizing burning and charring.

• Inert Gas: Used for flammable materials such as cotton or paper, ensuring safety and clean edges.

Auxiliary vapor also protects the focusing lens from contaminants like smoke and dust, prolonging its lifespan. This added efficiency enhances both productivity and machine durability.

The benefits of laser leather cutting extend beyond just precision. This method offers an innovative approach that saves time, materials, and effort while delivering top-tier results.

The laser beam cuts without physical contact, ensuring the material remains free from mechanical deformation. No wear and tear occur on the cutting tool, reducing maintenance costs.

The cutting ability is unaffected by the material’s hardness, making it suitable for all leather types, including genuine, synthetic, and embossed varieties. The non-contact nature also ensures the machine’s durability over long-term use.

The laser achieves narrow, straight slits with exceptional precision, even for intricate patterns. Smooth, clean edges eliminate the need for post-processing like sanding or trimming.

Materials are used efficiently with computer-aided designs, maximizing productivity and minimizing scrap. This precision allows users to create designs that were previously difficult or impossible with manual methods.

• Laser systems integrate seamlessly with automation equipment, making them suitable for mass production.

• The laser’s adaptability supports unlimited profiling cuts, enabling detailed and complex designs.

• It can switch between cutting, engraving, and perforating with minimal adjustments, streamlining production.

• Operators can easily modify designs through software, enhancing customization options for clients.

Laser leather cutting outshines both traditional tools and thermal methods by delivering superior precision, efficiency, and design versatility.

• Laser beams concentrate heat on a much smaller area than traditional thermal tools, ensuring finer incisions.

• The minimal heat-affected zone prevents excessive deformation, preserving the material's texture and quality.

• Other thermal methods often leave rough or uneven edges, while laser cutting provides a polished finish.

• Laser systems also consume less energy compared to traditional thermal cutters, reducing operational costs.

• Manual tools often require significant effort and are prone to human error, leading to inconsistent results.

• Laser cutting eliminates these issues by automating the process, ensuring consistent precision every time.

• Unlike manual tools, which may not work effectively on hard materials, lasers can handle any leather hardness effortlessly.

• The use of advanced software allows users to plan complex layouts, reducing material wastage and optimizing production.

Laser cutting of leather is the best and most productive way of treating leather. It shows unbeatable precision, speed, and adaptability in high-volume production lines or in making intricate designs, and thus, this has become the mainstay solution both for industries and artisans. Laser leather cutting, integrating modern technology and innovative techniques, ensures quality results while maintaining material integrity.

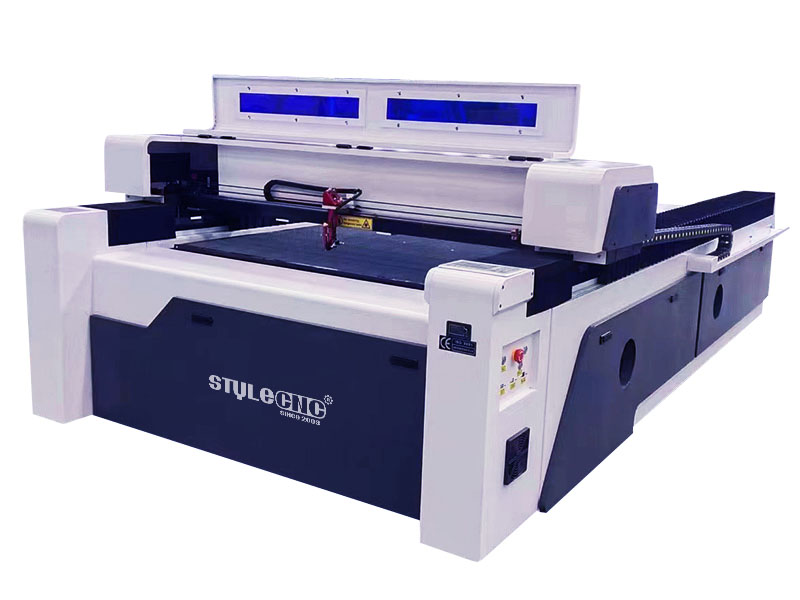

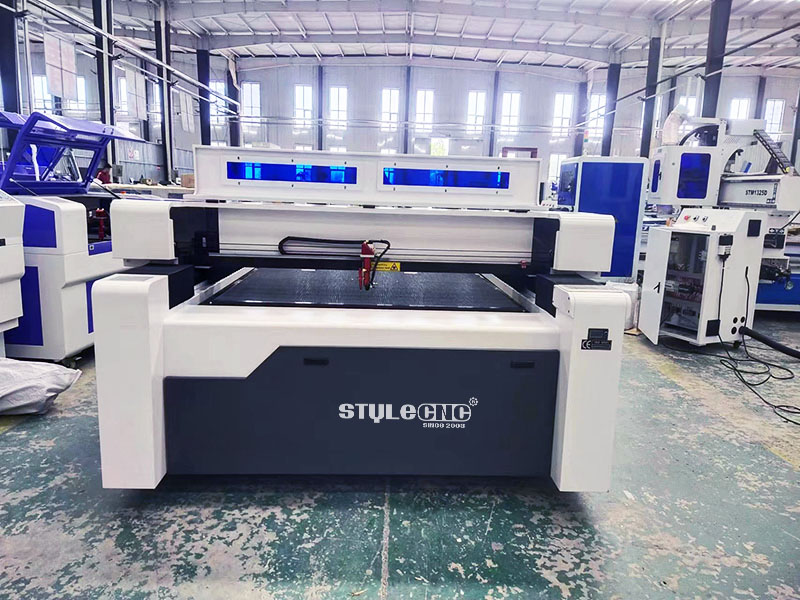

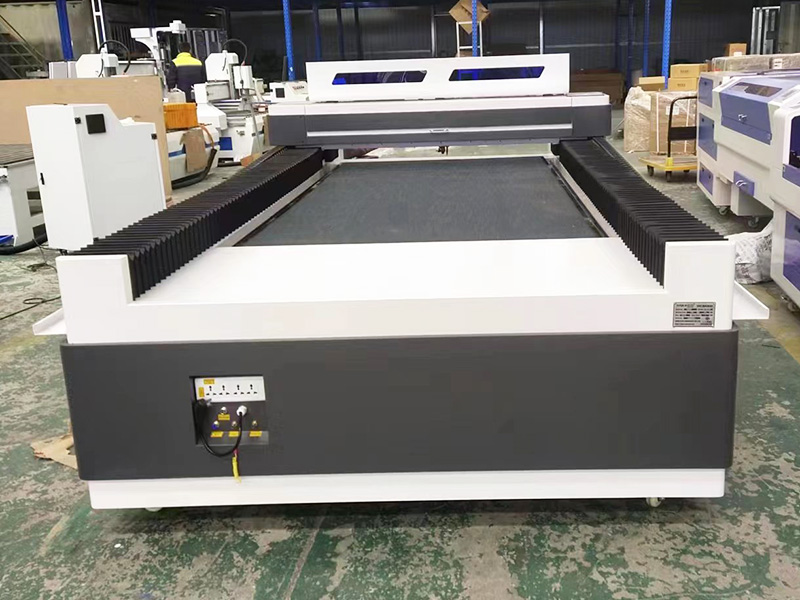

1. Open-type worktable, which is widely used in cutting and engraving large size materials with high precision and speed, such as advertising, light industry, woodworking, arts and crafts.

2. Powerful stepper motors and high imported HIWIN linear guide ensure the fast speed and stability.

3. DSP control: RD6442 control system with high speed, stability, anti-interference ability. Advanced USB control and Flash Disk (U Disk) off-computer control system are optional.

4. CO2 laser tube 80W, 100W, 130W, 150W, 180W for option.

5. Professional software for laser machine, which supports PLT, DXF, BMP, AI, DSF formats, it is applicable for drawing programs such as CorelDraw, PhotoShop, AutoCAD, etc.

6. The laser cutting machine has 512 memory which can allow to save and store files in the machine and can work without connecting computer.

7. Nice design of dust-proof structure for X, Y axis to ensure longer lifespan of the laser machine.

8. The stability and integrity design idea with advanced industry cooling system and water alarm automatic protection function, which will improve the stability and safety of continuous operate.

9. Using flying path design, unique structure, small optical path deviation, high stability, easy to adjust.

10. Independent R&D efficient laser power: The laser machine adopts new high-voltage switch-mode, PWM master control technology, which is more stable.

| Model | STJ1325 |

| Working Area | 1300x2500mm |

| Laser Power | 80W/100W/130w/150W/180W |

| Laser Type | CO2 laser |

| Laser Power Control | 10%-100% software setting |

| Cutting Speed | 0-60000mm/min |

| Preposition Accuracy | ±0.01mm |

| Min Shaping Character | English 1*1mm |

| Resolution | 4500DPI |

| Graphic Format Supported | BMP, AI, DST, CDR, PLT, DXF, JPG, PGN |

| Software Supported | CorelDraw, Photoshop, AutoCAD, LaserCut, Tajima |

| Driving System | Stepper Motor |

| Control System | Rdworks |

| Cooling Mode | Water Cooling |

| Working Voltage | AC 110-220V±10%, 50-60Hz |

| Package | Wooden Case |

| Optional Parts | Rotary Attachment Honey Comb Worktable Motorized Up-Down Table (Z axis) |

Proper maintenance of your laser leather-cutting machine is crucial to keep it running optimally and with maximum performance. Routine servicing not only saves you from costly repairs but also ensures uniform quality in cuts. Here are 10 steps to maintain your machine in excellent working condition.

1. Regular cleaning of the lens and mirrors for dust and debris that can block the path of the laser beam and prevent the machine from cutting as precisely as it should.

2. Wipe the components with a soft, lint-free cloth dipped in a mild cleaning solution, as scratches may make the focus and quality of cuts poor.

3. The air assist system makes the cut clean by blowing off the smoke and debris. Clogged nozzles cause burning or uneven cuts in the material.

4. Clean the nozzle regularly, along with air compressor filters, for smooth airflow, which is an essential factor in consistent performance related to cutting.

5. Smearing the rails, bearings, and motors minimizes friction, thus preventing wear on the moving parts.

6. Lubricants specified by the manufacturer will be used for all mechanical parts to minimize breakdowns and retain machine accuracy.

7. After some time, bolts and other mechanical parts may get looser, creating a source of possible vibration or misalignment, which may lead to poor performance in the machine.

8. These also need periodic inspection and tightening to maintain functionality and avoid any damage in the system.

9. The power of a laser deteriorates with time, which badly affects the machine's cutting capability. Through routine calibration, the power of the laser remains consistent to provide perfect cuts.

10. If the laser is not calibrated properly, it will result in an uneven cut and may further cause damage to the materials, reducing the productivity of the overall machine.

Great laser. Works well for leather fabric, does what it is supposed to do. I get genuine leathers cut so much faster and easier. Be careful though, the laser will cause serious eye injuries if you approach it without safety glasses and goggles.