Industrial 4x8 CNC Router Machine for Wood Door Making

Looking for a full-size professional CNC machine with cutting and relief carving to make personalized wood doors? Here is the best industrial 4x8 CNC router of 2024 with 3 spindles for custom home doors, cabinet doors, and any wooden doors made of cherry, alder, mahogany, walnut, oak, poplar, hickory.

- Brand - STYLECNC

- Model - STM1325-3TA

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 4' x 8' (48" x 96", 1300mm x 2500mm)

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

Looking for a full-size professional CNC machine with cutting and relief carving to make personalized wood doors? Here is the best industrial 4x8 CNC router of 2024 with 3 spindles for custom home doors, cabinet doors, and any wooden doors made of cherry, alder, mahogany, walnut, oak, poplar, and hickory.

STM1325-3TA is a full-size 4x8 CNC router for plywood, MDF, and solid wood door making, which is the most popular CNC machine with three spindles, and a 4' x 8' (48" x 96" in inches) tabletop for full sheet woodworking. 4x8 stands for the table size with 4 feet (48 inches, 1300 millimeters) in width, and 8 feet (96 inches, 2500 millimeters) in length, which is also known as 4' x 8', 4 by 8, 4 feet by 8 feet, 4 ft x 8 ft, 48x96, 48" x 96", 48 inches by 96 inches, 1325, 1300mm x 2500mm, 1300mm*2500mm, and 130cm x 250cm.

Why Choose a 4x8 CNC Router for Wood Door Production?

A 4x8 CNC router is a popular choice for producing wood doors due to its precision, size, and versatility. Large sheets of wood, such as plywood or MDF, which are frequently used to make doors, are easily handled by this equipment. The worktable dimensions are represented by the 4x8 size, which enables it to process conventional sheet sizes without requiring them to be trimmed down beforehand. This reduces waste and makes effective use of the entire piece of wood.

One of the key benefits of a 4x8 CNC router is its ability to create accurate and reliable designs. With remarkable accuracy, the CNC router can produce both straightforward flat-panel doors and intricate designs. Human mistake is frequently present in traditional methods; however, CNC machines eliminate this possibility by automating the cutting process.

The machine's versatility is another consideration in the selecting process. It is capable of cutting, engraving, and carving a broad variety of materials. This makes it ideal for custom wood door designs, as customers frequently want ornamental components or patterns that are distinctive. The 4x8 CNC router is perfect for producing wood doors since it has the adaptability to satisfy these demands.

Additionally, using a CNC router improves speed and efficiency. Manual labor can be slow and inconsistent, while the CNC router can quickly create multiple doors with the same precision and quality. This is especially beneficial for larger production runs, where maintaining uniformity is essential.

Features of Industrial 4x8 CNC Router Machine for Wood Door Making

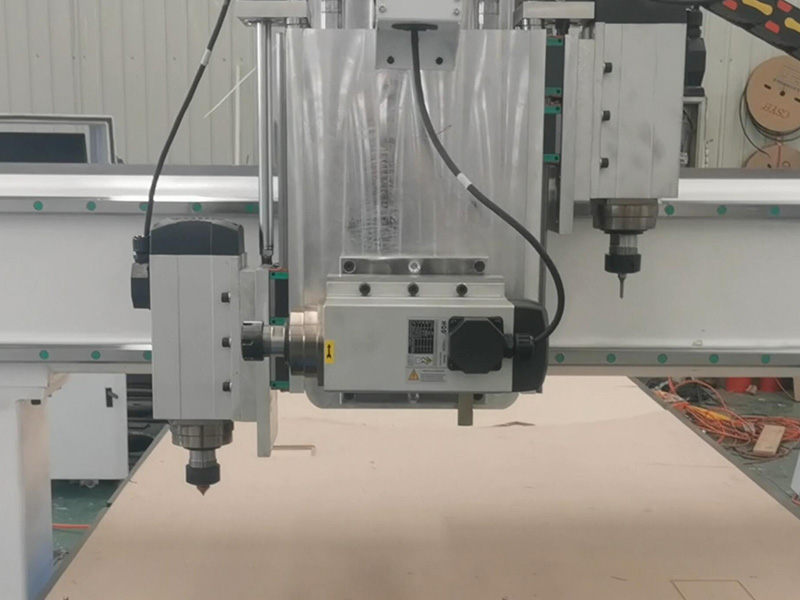

• The three-process is smart and economical equipment with an automatic tool changer. Through the automatic change of three independent electric spindles, the automatic machining of multi-process is completed.

• The tool changer mode is the immediate and instant change of the spindle.

• The lathe bed adopts a strong welded steel tube to avoid distortion.

• The middle spindle can swing 180 degrees.

• The high-power air cooling spindle is used to achieve precision higher, longer service life, uniform speed, running stability, and rapidly changing the necessary props at random which can save the machining time and enhance the working efficiency.

• Square linear rail with high accuracy and heavy burthen.

• The screw rack transmission with high precision, and the servo motor with high resolution and fine mixing, the straight guide rail with high rigidity, levelness, and flexible transmission.

• All processes will be completed after the startup of the tool one time to shorten the tool change and matching time, thus the tool applies to the product for which the tool has to be changed several times.

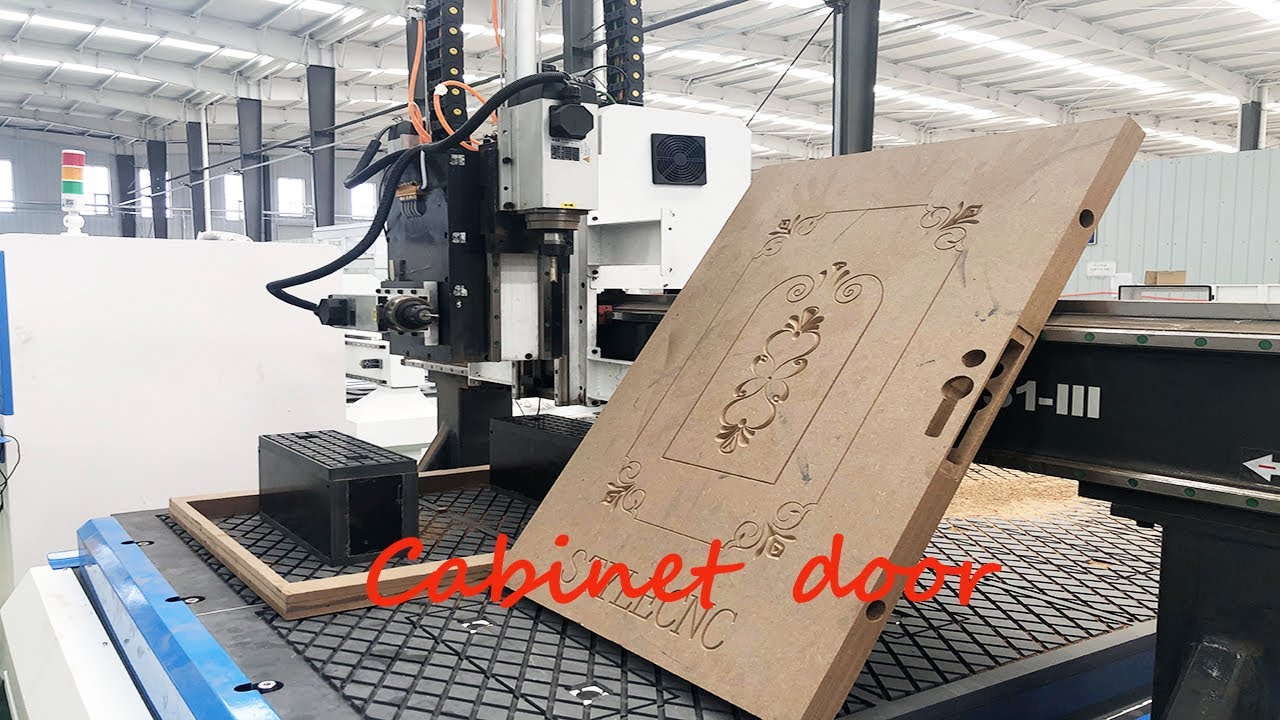

• The industrial CNC wood door-making machine is applicable to produce cupboard doors, solid wood doors, computer tables, panel furniture, and so on, it is used for the works of high-density boards with large areas and production, plane carving, cutting, 3D relief carving.

Applications of 4x8 Industrial CNC Router Machine for Wood Door Making

• Furniture Making: Wooden doors, cabinets, plates, office and wood furniture, tables, chairs, doors, and windows.

• Woodworking: Voicebox, game cabinets, computer tables, sewing machines table, instruments.

• Plate processing: Insulation part, plastic chemical components, PCB, inner body of the car, bowling tracks, stairs, anti-bate board, epoxy resin, ABS, PP, PE, and other carbon mixed compounds.

• Decorations: Acrylic, PVC, MDF, artificial stone, organic glass, plastic, and soft metals such as copper, aluminum plate engraving and milling process.

Technical Parameters of Industrial 4x8 CNC Router Machine for Wood Door Making

| Brand | STYLECNC |

| Model | STM1325-3TA |

| Table Size | 4x8 |

| Working Area | 1300x2500x300mm |

| Traveling Positioning Accuracy | ±0.03/300mm |

| X,Y,Z Reposition Accuracy | ±0.03mm |

| Table Surface | Vacuum Table |

| Frame | Welded Structure |

| X, Y Structure | Rack and Pinion Drive, Hiwin Rail Linear Bearings |

| Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

| Max. Rapid Travel Rate | 33000mm/min |

| Max. Working Speed | 25000mm/min |

| Spindle Power | 6KW |

| Spindle Speed | 0-18000RPM |

| Drive Motors | Servo System |

| Working Voltage | AC380V/50Hz,3PH (Option: 220V)) |

| Command Language | G Code |

| Operating System | LNC control system |

| Computer Interface | USB |

| Software Compatibility | Type3/UcancameV9 Software (Option: Artcam Software) |

| Running Environment Temperature | 0 - 45 Centigrade |

| Relative Humidity | 30% - 75% |

| Packing Size | 3500X2280X2200mm |

| N.W. | 2000KG |

| G.W. | 2300KG |

| Price Range | $14,200.00 - $21,000.00 |

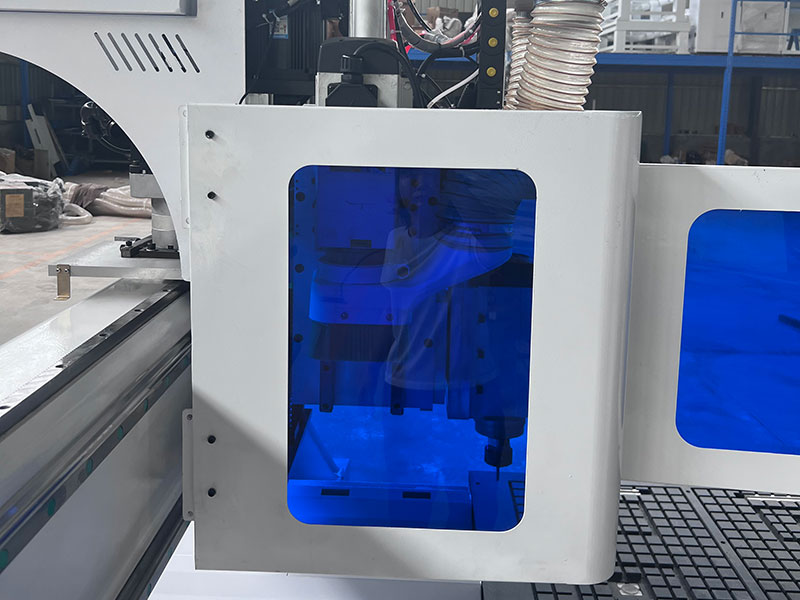

4x8 Industrial CNC Wood Door Making Machine Details

Industrial 4x8 CNC Router Machine for Wood Door Making Projects

Efficiency and Productivity Benefits for Manufacturers

The 4x8 CNC router can help manufacturers become more productive and efficient. Utilizing a 4x8 CNC router ensures consistent operation during the wood door-making process, reducing labor expenses and mistakes.

• Automated Cutting: The CNC router automates much of the cutting process, reducing the need for manual labor. This saves time and allows workers to focus on other tasks.

• Continuous Operation: The machine can run for long periods without stopping. This is essential for large production orders where continuous output is necessary to meet deadlines.

• Reduces Errors: By automating the process, the CNC router eliminates common human errors. This results in consistently accurate cuts and fewer wasted materials.

• Optimizes Material Usage: The software calculates the best way to cut the material, minimizing waste. Over time, this can lead to significant cost savings, especially in large-scale production.

• Quick Design Adjustments: Changing designs or making adjustments is easy with a CNC router. Simply load a new design file, and the machine is ready to start a new project without delays.

Maintenance Tips for Your CNC Router Machine

CNC router machines need regular maintenance to stay in top condition. Simple care routines can prevent unexpected breakdowns, improve cutting accuracy, and extend the machine’s lifespan. With these straightforward maintenance tips, you can ensure smooth operation and long-term productivity from your CNC router, saving time and reducing costly repairs.

1. Dust and wood debris can build up and affect performance. After each job, use a vacuum or compressed air to remove debris from the cutting area and other parts.

2. Regular lubrication of moving parts, such as rails and spindles, prevents friction and wear. Refer to the machine’s manual for the recommended type of lubricant and frequency.

3. Check the cutting tools for wear and tear. Dull or damaged bits can result in poor-quality cuts. Replace them as soon as you notice any issues to maintain accuracy.

4. Regularly calibrate your CNC router to ensure it’s cutting accurately. Calibration ensures that the machine's movements are precise and that the final product matches the design specifications.

5. Ensure all power cables and connections are secure. Loose connections can lead to malfunctions or cause the machine to stop unexpectedly.

6. Keep your machine’s software up to date. Software updates provide improved performance and fix any bugs, ensuring the machine runs efficiently.

Service & Support for Industrial 4x8 CNC Wood Door Making Machine

1. The 4x8 industrial CNC wood door-making machine is guaranteed for one year. If the main components have problems during the warranty period, we will replace them for you free of charge.

2. Free training course at our plant.

3. Lifetime maintenance free of charge.

4. 24-hour online service each day, free technical support.

5. We will provide the consumable parts at an agency price when you need replacement.

6. Our staff can be sent to your company to install or debug if necessary.

7. The 4x8 industrial CNC wood door-making machine has been adjusted before shipping.

Stuart Brown

Douglas C Rasia

K. Algra

Martin Grace

Worked great for what I needed it for. Fit my S1-III perfectly. All parts needed to operate to the router were included in the kit. Has more functionality than what I needed for my project, which is great for future work.

Costel Vodarici

Joe Menafra

Everything in this CNC kit was perfect, assembly is pretty straightforward, easy to connect to my laptop, even ran a few cuts. Better than I could imagine doing it.

Mark Moore

I've never used a CNC kit like this before only hand routers. I purchased the S1-III last month and it runs great with no issues. Great manufacturer.