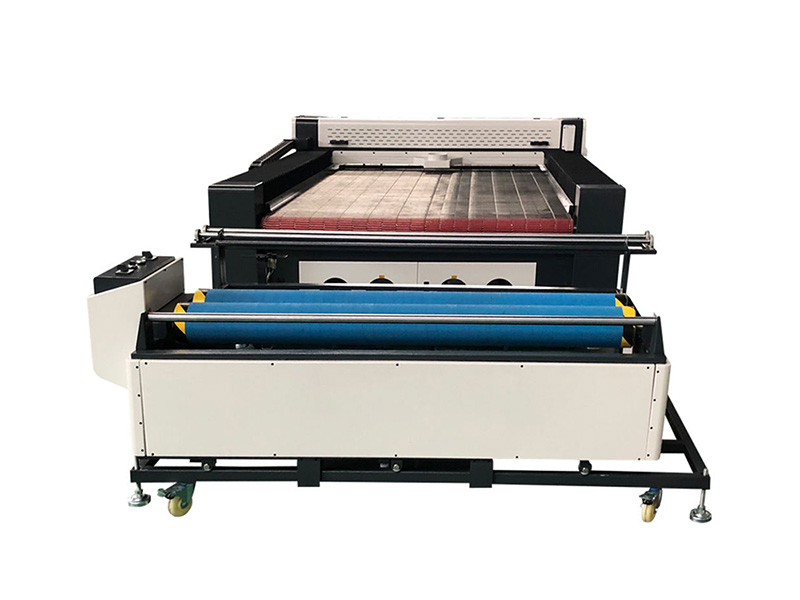

Automatic CO2 laser cutter with roll feeder is used to cut clothing patterns, festival clothing, cloth face masks, textile garment, and fashion apparel. Now the CO2 laser fabric cutting machine with roller table and automated feeding system for sale at cost price.

An automatic CO2 laser cutter for clothing and garments is a high-tech tool used to precisely cut fabric and other materials with incredible accuracy. It uses a focused beam of CO2 laser light to vaporize the material, creating clean, sharp edges without the need for physical cutting tools. This method ensures that intricate patterns and designs can be achieved effortlessly, making it ideal for fashion design and garment production.

The CO2 laser cutter offers numerous advantages over traditional cutting methods. It can handle various fabrics, including cotton, polyester, and leather, and it’s especially useful for materials that are difficult to cut with conventional methods. The machine’s precision reduces fabric waste, leading to more efficient production and cost savings. It also minimizes the need for manual labor, speeding up the production process.

Additionally, these laser cutters can easily be programmed to follow intricate designs, allowing for customization and versatility in garment production. Whether it’s for small custom orders or large-scale garment manufacturing, the CO2 laser cutter enhances creativity, efficiency, and quality in the clothing industry.

1. The automatic feeding system (roll feeder or roller table) is added to save time and cost and to improve work efficiency.

2. The roller table adopts a special automatic feeding device, and convenient processing objects move freely on the surface of the cutting machine.

3. Fabric auto-collecting device is very convenient for users to collect clothes. The window is fireproof glass, making the machine more secure.

4. Liner guide rail and precision gear for transmission to ensure accuracy and high speed, open stainless meshed worktable to ensure convenient operation and wear resistance.

5. A crawler correction device can prevent crawler belt dislocation when working.

6. The moving system adopts Taiwan Hiwin linear guide and precision gear, matched up with the advanced stepper motor to ensure working accuracy.

7. To fully support design software, such as CAD, CORELDRAW, PHOTOSHOP, and friendly man-machine interface, live close to the industry needs.

8. CCD camera (Charge-coupled Device camera) is optional, automatic locating cutting machine with a camera.

| Model | STJ1830A |

| Table Size | 1800*3000mm |

| Laser Power | 150W |

| Laser Type | Sealed CO2 laser tube |

| Laser Locating Precision | ≤±0.01mm |

| Cooling Type | Water Cooling |

| Max Moving Speed | 1600mm/s |

| Max Cutting Speed | 1400mm/s |

| Laser Output Control | 0-100% set by software |

| Controlling Software | RD Control system |

| Graphic Format Supported | DST, PLT, BMP, DXF, DWG, AI, LAS |

| Drive System | Stepper motor or servo optional |

| Auxiliary Equipments | Exhaust fan and air exhaust pipe |

| Power Supply | AC110V/220V±10%, 50H/60HZ |

| Working Environment | Temperature 0-45°C, Humidity 5-95% |

The automatic CO2 laser cutting system has transformed several industries by offering high-precision cutting for a variety of materials. In the apparel, clothing, and garment industries, this system provides a significant advantage by automating the cutting process, ensuring faster production speeds, and reducing material waste. Here are some major applications:

• Textile and Garment Industries: The CO2 laser cutting system is widely used for cutting fabrics in garment production. It handles various types of textiles, including cotton, polyester, and mixed fabrics, enabling intricate patterns and design cuts. It’s perfect for mass production or customized designs.

• Leather and Automotive Interiors: CO2 lasers can cut leather materials with ease, making them ideal for automotive upholstery, furniture, and fashion accessories like bags and shoes. The precision ensures clean edges and reduces the need for finishing work.

• Home Décor and Fabrics: The system is perfect for creating decorative cloth items, carpets, or wall coverings, allowing for the production of complex patterns or custom-sized products.

• Industrial Fabrics: CO2 laser cutters are also used for cutting heavy industrial fabrics, such as those found in tents, tarps, or safety gear, providing accurate cuts even on thick materials.

When choosing between a manual and an automatic CO2 laser cutter for apparel manufacturing, it's essential to understand the differences in efficiency, precision, and production scalability. Both types offer advantages, but the choice ultimately depends on your business needs, budget, and production goals. Here's a simple comparison to help guide your decision.

| Feature | Manual CO2 Laser Cutter | Automatic CO2 Laser Cutter |

| Ease of Use | Requires more operator skill and control. | Minimal operator intervention; fully automated. |

| Precision | Moderate precision depends on operator skill. | High precision with automated adjustments. |

| Speed | Slower production speeds due to manual setup and adjustments. | Faster production due to automated processes. |

| Customization | Best for small, custom orders. | Ideal for both small and large-scale production with high customization. |

| Labor Requirements | Higher labor costs due to manual operation. | Reduced labor costs due to automation. |

| Cost | Generally more affordable upfront. | Higher initial investment but cost-effective in the long run. |

| Scalability | Limited scalability for mass production. | Easily scalable for large or growing businesses. |